- Production Machines

- Cutting Machine

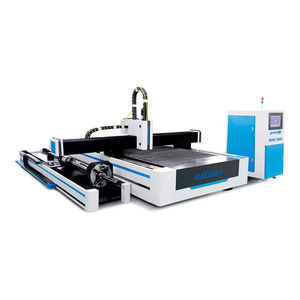

- Fiber laser cutting machine

- Anhui Zhongrui Machine Manufacturing Co., Ltd.

Fiber laser cutting machine 1530for aluminumfor stainless steelfor carbon steel

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for aluminum, for stainless steel, for carbon steel, for brass

- Product handled

- sheet metal

- Control type

- CNC

- Applications

- for industrial applications, for the automotive industry, for metal fabrication, for processing industry, for shipbuilding

- Other characteristics

- high-precision, high-speed, with water cooling, alloy steel

- X travel

600 mm, 1,300 mm, 1,500 mm, 2,000 mm

(24 in, 51 in, 59 in, 79 in)- Y travel

600 mm, 900 mm, 3,000 mm

(24 in, 35 in, 118 in)- Cutting speed

25,000 mm/min

(16.404 in/s)- Laser power

500 W, 1,000 W, 2,000 W, 3,000 W

Description

Applicable Materials: Metals like Stainless Steel, Carbon Steel, Alloy Steel, Silicon Steel, Titanium Alloy, Brass and Aluminium etc.

Applicable Industries: Automobile Industry, Mold Manufacturing Industry, Mechnical Equipment, Shipbuilding Industry, Aircraft Industry, Hardware, Decoration and Metal Processing Service.

1) The world’s most advanced stable fiber laser with features such as long lifetime up to 100,000hours, high quality laser beam with small focus spot, high brightness, high conversion rate and maintenance-free, ensures high quality processing with high stability.

2) Scientific reasonable gantry type design , high strength welding machine body and CNC control system ensure the stability during the working process.

3) Imported linear guide rail with high speed and high accuracy is much more suitable for high precision cutting, specially for cutting metal plates with thickness less than 10mm.

4) High cutting speed: The cutting speed is 2-3 times higher than that of the same power Co2 laser cutting machine.

5) High electro-optical conversion rate: 3 times higher than the Co2 laser cutter, saving energy and more environmental.

6) Very low cost-in-use: Power consumption of the whole machine is only 20%-30% of Co2 laser machine.

7) Operation and maintenance is more convenient: Fiber transmission needn’t adjust the laser path.

Catalogs

No catalogs are available for this product.

See all of Anhui Zhongrui Machine Manufacturing Co., Ltd.‘s catalogsOther Anhui Zhongrui Machine Manufacturing Co., Ltd. products

FIBER LASER CUTTING MACHINE

Related Searches

- Cutting system

- Industrial press

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Hydraulic press

- Forming press

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Automatic press

- Fabric cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.