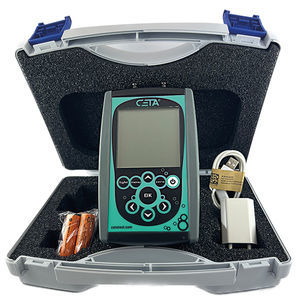

Differential pressure decay leak tester CETATEST 815pressure riseelectro-pneumaticfor automotive applications

Add to favorites

Compare this product

Characteristics

- Type

- differential pressure decay, pressure rise, electro-pneumatic

- Applications

- for automotive applications, for packaging, for plastics weldings, blister, for bottles, for vehicle pneumatic systems, for valves, for pipe, for oil filters, relay, for aeronautical applications, for the plastics industry, for automation, expansion tank, for sensors, for empty containers, for pipettes, for cans, for seal integrity, breathing apparatus and face mask, for injection valves, for empty aerosol cans, for vessels

- Other characteristics

- automatic, compact, USB, Profibus

Description

The CETATEST 815 is a full automatically working leak tester for the detection of untight parts within the cycle time of the production process. The pressure in the test part volume is compared with the pressure in a tight reference volume.

The CETATEST 815 can be equipped with a multitude of test modes and is applicable for a lot of applications. The 24 bit AD converter und its high clock rate allows short test times.

The CETATEST 815 can be delivered as 2 channel test device. Parameter can be exported resp. imported using an USB storage device. Measurement series and measurement curves can be stored also.

NEW:

Leak Tester Series CETATEST 815 Low Pressure with Electronically Controlled Pressure Ranges (± 5 mbar and ±50 mbar)

In the right picture: Examples of test parts that CETA customers test with the CETATEST 815.

Pressure Sensors - Differential pressure sensor, gauge pressure sensor

Pressure ranges - -1 bar, +/-5 mbar, +/-50 mbar, 200 mbar, 1000 mbar, 6 bar, 10 bar, 20 bar, 30 bar, negative gauge pressure and positive gauge pressure ranges can be combined, (e.g. -1 bar / + 1 bar)

Measurement ranges - ± 500 Pa / ± 5,000 Pa (displayed resolution: 1 Pa, internal resolution: effective 0.01 Pa)

Result units - Pa, hPa, PSI, Pa/s, hPa/s, mbar*l/s, ml/min, ml/h, l/min, l/h, mmHg, Torr, mmWs

Pressure controller - Mechanical, electronical

Test modes - Pressure decay, optional: sealed component, ram pressure, pressure steps, pressure rise (with double leak connector)

Dimensions - 345 mm x 145 mm x 435 mm (W x H x D)

Two channel operation - As option available

Typical applications - Components that should be waterproof, oil-tight or gas proof

Exhibitions

Meet this supplier at the following exhibition(s):

CETA Webinar - Leak testing of encapsulated test parts

16-16 May 2024 Hilden (Germany)

More information

Related Searches

- Pressure gauge

- Leakage detector

- CETA leak tester

- Differential pressure indicator

- Digital pressure indicator

- Gas leakage detector

- Absolute pressure indicator

- Leakage detector with integrated display

- CETA pressure leak tester

- Calibration pressure indicator

- CETA automatic leak tester

- Leakage detector with digital display

- Test pressure gauge

- Packaging leak testing device

- Laboratory pressure indicator

- Compact pressure indicator

- Vessel leak testing device

- Leak tester for automotive applications

- Bottle leak tester

- USB leak testing device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.