- Machine-tools

- Machining Center

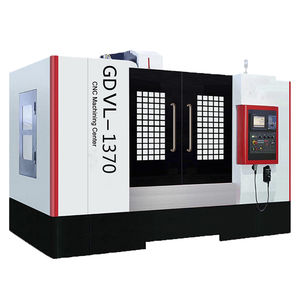

- 3-axis machining center

- Dongguan Gooda Machinery Manufacturing Co., Ltd.

3-axis CNC machining center GDGM-6036RNChorizontalwith fixed portalcolumn type

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- horizontal

- Structure

- with fixed portal, column type, fixed-bed

- Machined material

- for aluminum

- Spindle mount

- BT 50

- Number of tool stations

- 24 tools

- Applications

- cutting, drilling, for large workpieces, for molds

- Other characteristics

- milling, high-speed, high-precision, CE

- X travel

6,500 mm

(256 in)- Y travel

3,800 mm

(150 in)- Z travel

1,250 mm

(49 in)- Rotational speed

3,000 rpm

(18,850 rad.min-1)- Power

30 kW, 37 kW

(40.79 hp, 50.31 hp)- Work feed X-axis

10,000 mm/min

(7 in/s)- Work feed Y-axis

10,000 mm/min

(7 in/s)- Table load capacity

36,000 kg

(79,366 lb)- Tool weight (max)

15 kg

(33.1 lb)- Tool-changing time

1.8 s

- Weight

75,000 kg

(165,346.7 lb)- Overall length

16,500 mm

(649.6 in)- Overall width

7,200 mm

(283.5 in)- Overall height

6,500 mm

(255.9 in)

Description

GDGM-6036RNC is a fixed beam and fixed column gantry machining center machine tool. It is developed based on the most popular, advanced and flexible machine tool design concepts in the world. It is suitable for aerospace, shipbuilding, power generation, military industry, heavy machinery, locomotives, machine tools, and textile machinery. , Printing machinery, automotive covering molds and other industries of various large-scale workpiece machining equipment.

The Features: The machine adopts the gantry structure of moving table. The bed is fixed, the worktable moves in the X direction on the bed; the ram moves in the Z direction on the sliding seat; the sliding seat and the ram move in the Y direction on the gantry beam; the X and Y axes adopt heavy-duty linear rails, Z The shaft is a plastic hard rail. The main shaft assembly is placed at the lower end of the ram; the whole machine has a reasonable layout, beautiful appearance and convenient operation.

Spindle box: We use high-speed BT50 spindle unit with center blowing.

Tool Magazine: We use disc magazine with high quality and stable functionality. (Optional)

Transmission: The three-axis motor and high-precision ball screw adopt a direct drive method. The ball screw is pre-tensioned and installed to improve transmission rigidity and positioning accuracy.

Other Dongguan Gooda Machinery Manufacturing Co., Ltd. products

CNC Machining Center Machine

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Gantry CNC machining center

- Drilling machine

- Milling CNC machining center

- Cutting CNC machining center

- Column type CNC machining center

- Applications CNC milling machine

- Aluminum CNC machining center

- BT 40 CNC machining center

- Bridge CNC milling machine

- Horizontal CNC machining center

- Drilling CNC machining center

- Precision CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.