- Production Machines

- Cutting Machine

- Sliding table saw

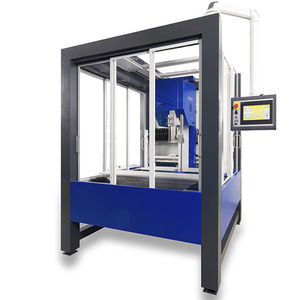

- DRAMET Draht und Metallbau GmbH

Diamond band saw BS200 Ssliding tablefor hard metalfor composites

Add to favorites

Compare this product

Characteristics

- Technology

- diamond band, sliding table

- Treated material

- for hard metal, for composites, for CFRP, for FRP, for graphite, for glass

- Applications

- for profiles, for the automotive industry, for sample preparation, for cylindrical products

- Other characteristics

- with cooling system, semi-automatic, vertical, precision, electric, variable-speed, manual actuation, with moving table, for laboratories, multipurpose, track

Description

The Diamond band saw BS200 S is an economically efficient laboratory machine with a fixed sawing unit

Passage (length, width) 200×200 mm, cutting length (X-axis) 200 mm. Floor space 800 x 714 mm, 1858 mm hight.

The Diamond band saw BS200 S has a sliding table that can be manually moved while sawing. During operation the sliding table can also be moved by its own weight.

In terms of sawing different thicknesses, the machine can be easily adjusted. Slice thickness can be verified by using the manual lock.

The Diamond band saw can be operated with a dry cut or alternatively with cooling. Under specific conditions a cooling creates more effective cuttings combined with higher rotational speeds and higher feed rates.

Functioning of the diamond saw machine BS 200 S

The BS200 S is composed of a band unit with two deflection rollers D = 230 mm with a passage (H x W) of 200 x 200 mm. The diamond saw band runs over two rollers in an endless loop. It is driven and pneumatically tensioned by the height-adjustable upper roller. The band is driven by a 750 W 3-phase current motor controlled by a frequency transformer. The band tension is set by the adjustable air pressure on the pressure reducer. The speed of the band can be set between 200 and 2200 m/min.

The workpiece table´s linear guidance can be tilted using an adjustment screw. The table moves with a constant feed force driven by its own weight without the need for manual operation.

It can be operated with a dry cut or alternatively with cooling. For dry cutting, a suction unit is attached to the exhaust connector provided. For the stainless version, pure water can be used for cooling.

VIDEO

Catalogs

The diamond band saw BS200 S

2 Pages

Other DRAMET Draht und Metallbau GmbH products

Diamond band saws

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Metal sawing machine

- Circular sawing machine

- Automatic sawing machine

- Band sawing machine

- Saw blade

- Horizontal sawing machine

- Precision sawing machine

- Profile sawing machine

- Aluminum sawing machine

- Plastic sawing machine

- Stone and concrete saw

- Vertical sawing machine

- Semi-automatic sawing machine

- Stone cutting system

- Electric sawing machine

- Glass cutting system

- Sawing machine with cooling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.