- Machine-tools

- Machining Center

- 5-axis CNC milling machine

- GF Machining Solutions

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

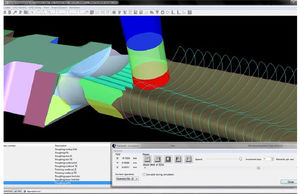

5-axis CNC milling machine MILL P seriesverticalHSK A-63HSK-T63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Spindle mount

- HSK A-63, HSK-T63

- Number of tool stations

- 60 tools, 30 tools, 120 tools, 80 tools

- Applications

- for the mold industry

- Other characteristics

- high-performance, high-precision, high-productivity

- X travel

500 mm, 800 mm, 1,400 mm

(20 in, 31 in, 55 in)- Y travel

600 mm, 800 mm, 1,300 mm

(24 in, 31 in, 51 in)- Z travel

450 mm, 500 mm, 1,000 mm

(18 in, 20 in, 39 in)- Rotational speed

20,000 rpm, 28,000 rpm

(125,664 rad.min-1, 175,929 rad.min-1)- Work feed X-axis

54,000 mm/min, 61,000 mm/min

(35 in/s, 40 in/s)- Work feed Y-axis

54,000 mm/min, 61,000 mm/min

(35 in/s, 40 in/s)- Work feed Z-axis

54,000 mm/min, 61,000 mm/min

(35 in/s, 40 in/s)- Table load capacity

Min.: 200 kg

(441 lb)Max.: 3,000 kg

(6,614 lb)

Description

Agility for the future: Mikron MILL P series delivers intelligent productivity to help mold and die manufacturers overcome their challenges. Rapid market developments and future-changing innovations challenge mold and die manufacturers’ ability to adapt to change. GF Machining Solutions provides these manufacturers with agility for the future with its Mikron MILL P series of five-axis, simultaneous Milling machines.The Mikron MILL P U Series is a very robust, stable and accurate machine center in a gantry-type design. This five-axis Milling solution is designed for high-performance machining applications. For best accuracy and surface finish by simultaneous operation, the machine has water-cooled direct drives in the rotary and swiveling axes. These axes can be clamped to reach even a higher stiffness during roughing. Workpiece access is made easy by the big door and the short distance to the work table. Thanks to its unique concept and its modularity, the machine ensures precise machining applications in both single item and fast, productive serial production.

Your precision center: 365 days a year

Get high material removal during roughing while achieving high precision on big, heavy parts and tightest tolerances after finishing.

Best surface finish on light or heavy parts

Make a great first impression and show off your overall capacity as a mold maker with the shiny surfaces this solution delivers to your high-value molds.

Highly flexible parts production

Get the flexible solution to help you master a wide range of parts production challenges: constantly changing part sizes, weights, batches and materials.

VIDEO

Catalogs

No catalogs are available for this product.

See all of GF Machining Solutions‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- GFMS - GF Machining Solutions CNC milling machine

- GFMS - GF Machining Solutions vertical CNC milling machine

- 3-axis CNC milling machine

- Drilling machine

- GFMS - GF Machining Solutions applications CNC milling machine

- GFMS - GF Machining Solutions precision CNC milling machine

- CNC drilling machine

- Turning-milling machine

- CNC turning-milling center

- 5-axis CNC milling machine

- GFMS - GF Machining Solutions high-precision CNC milling machine

- Vertical drilling machine

- Rigid CNC milling machine

- High-performance CNC milling machine

- Compact CNC milling machine

- CNC milling machine for the mold industry

- 5-axis turning-milling center

- High-productivity CNC milling machine

- CNC milling machine for the automobile industry

- 24 tools CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.