- Building - Construction

- Construction and Mining Equipment

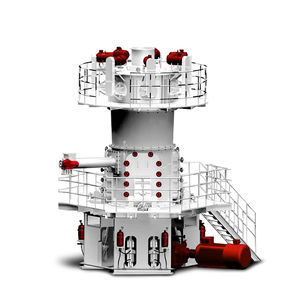

- Vertical roller mill

- Henan LIMING Heavy Industry Science and Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Vertical roller grinding mill LM190Kverticalfor limestonestone

Add to favorites

Compare this product

Characteristics

- Technology

- vertical roller

- Orientation

- vertical

- Product applications

- for limestone, stone, concrete, for ore, for cement, for clinker

- Other characteristics

- automatic, high-capacity, high-performance, large, high-pressure, high-speed

- Final grain size

Min.: 45 µm

Max.: 170 µm

- Output

Min.: 23 t/h

(14 lb/s)Max.: 72 t/h

(44 lb/s)- Motor power

450 kW, 500 kW

(611.83 hp, 679.81 hp)

Description

LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years’ mill experience. LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical industry, non-metallic mineral. It is used to grind granular and materials into powders with required fineness.

1. Low Investment Cost.

This mill itself can crush, dry, grinding, classifying, so the system is simple, and occupation area is about 50% of ball mill system.

2. Low Operation Cost.

High efficiency, Less wear and tear

3. High Drying Ability.

As the hot air inside contacts directly with the material, drying ability is higher, and it saves energy. By regulating the air temperature, it can meet requirements with different humidity.

4. Simple and reliable operation.

⑴ It is equipped with automatic control systems, so remote control makes it easy to operate. ⑵ It is equipped with one device,which prevents the roller from contacting with the liner directly, and avoids the destructive impact and severe vibration.

5. The stability of product quality.

As the material stays in the mill for a short time, it is easy to detect and control the product particle size and chemical composition, to reduce duplication of milling, stable product quality.

6. Maintenance convenience.

By repairing fuel tank, rotating the arm, it is fast to replace the roller sleeve, and liner, and reduce the downtime loss.

7. Environmental protection.

It is with small vibration, low noise, and the overall sealing. The system works under negative pressure, so there is no dust going out. It meets the requirements of the state Environmental Protection.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Henan LIMING Heavy Industry Science and Technology‘s catalogsOther Henan LIMING Heavy Industry Science and Technology products

Grinding Mill

Related Searches

- Liming crusher

- Liming stationary crusher

- Liming mobile crusher

- Liming impact crusher

- Liming jaw crusher

- Liming high-capacity crusher

- Liming primary crusher

- Liming secondary crusher

- Liming mineral material crusher

- Liming compact crusher

- Crawler crushing and screening plant

- Liming cone crusher

- Liming building material crusher

- Liming fine crusher

- Liming stone crusher

- Liming sand production crusher

- Liming tertiary crusher

- Coal crushing plant

- Liming limostone crusher

- Liming vertical-shaft impact crusher

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.