- Environment - Health - Safety

- Air Treatment and Noise Management

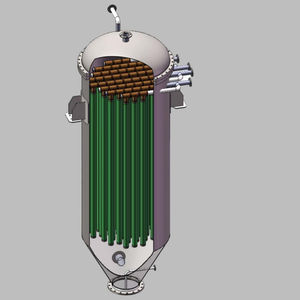

- Gas filter

- Henan Sinofiltec Technology Co.,Ltd

Heated gas filter gascartridgepressure

Add to favorites

Compare this product

Characteristics

- Designed for

- gas

- Filtration element

- cartridge

- Filtration method

- pressure

- Applications

- industrial, process, fine filtration, for high-pressure applications, for chemical applications, exhaust

- Material

- metal

- Mounting

- flange, thread connection, weld, ceiling-mounted

- Cleaning

- continuous, washable, self-cleaning, with pneumatic cleaning

- Fluid specification

- heated gas

- Other characteristics

- high-efficiency, high-temperature

- Operating pressure

Max.: 35 Pa

(0.005 psi)Min.: 1 Pa

(0 psi)- Filtration size

Max.: 100 µm

Min.: 3 µm

- Flow

Max.: 6,500 m³/h

(229,545.334 ft³/h)Min.: 100 m³/h

(3,531.467 ft³/h)- Fluid temperature

Max.: 450 °C

(842 °F)Min.: 260 °C

(500 °F)

Description

Hot Gas Filter System | High Temperature Gas Filtration

The Hot gas filter usually filters at an operating temperature higher than 260℃(500°F), and the traditional filter medium is not used anymore in such high temperature gas. The industrial pulse hot gas filter developed by Saifilter Company is mainly used to provide solutions in the fields of the utilization of waste heat utilization, from industrial high temperature flue gas and the purification and recovery of high-temperature gas. Because filter medium adopts composite metal fiber to directly purify the high temperature gas, remove the collected dust particles from the surface of the filter elements effectively, this process is usually carried out when the hot gas industrial dust collector is running online, it does not interrupt or interfere with the technological process except for very small pressure peaks (or "overpressures").

Hot Gas Filter Features and Benefits

Easy to clean. The difference from the ordinary bag filter is that the forced cooling, of the gas, is not necessary for the early stage. It solves the problems of other industrial filter elements that are easy to suffer from deformation due to not high temperature resistance or high temperature, the poor performance of the reverse blowing regeneration, the poor filtering capability, and efficiency, the difficulty of discharging the filter with adhesion, etc.

Other Henan Sinofiltec Technology Co.,Ltd products

Filtration System

Related Searches

- Filter with cartridge

- Filter cartridge

- Industrial filter cartridge

- Filter for industrial applications

- Pressure separator filter

- Fine filter cartridge

- General purpose filter cartridge

- Water filter cartridge

- Gas pre-filter

- Process separator filter

- High-efficiency pre-filter

- Pleated filter cartridge

- Self-backwashing filter

- Chemical product filter cartridge

- Air filter cartridge

- Easy cleaning pre-filter

- Membrane filter cartridge

- Flange-mount filter

- Fine filtration filter

- Filter for chemical applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.