- Production Machines

- Forming Machine

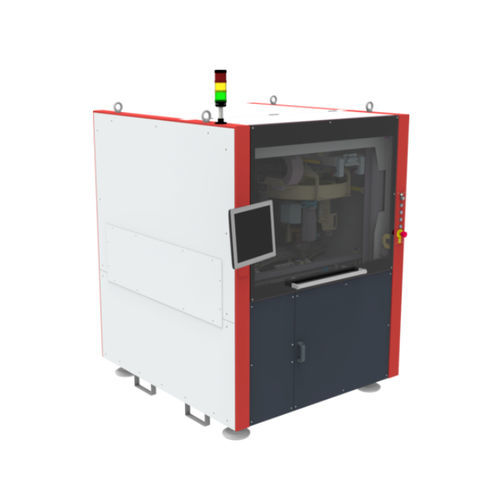

- Automatic press

- IPTE Factory Automation n.v.

Automatic press FLEXPRESSER IIwith conveyorcontinuousprocess

Add to favorites

Compare this product

Characteristics

- Control

- automatic

- Other characteristics

- continuous, with conveyor

- Applications

- process

- Force

10 kN, 7,000 kN

Description

The FlexPresser II is a fully automatic inline system for high dynamic pressing processes. The panel is transported into the work position via SMEMA interface on e.g. an edgebelt conveyor system.

Pins or connectors to be pressed in can be presented by several types of feeding systems (e.g. Trayfeeder, Stickfeeder, Bowlfeeder, etc.), which are connected to the standard FlexPresser II interface.

The pressing process with up to 7kN (or 10 kN) is done with way/force control and programmed on CAD data basis to realize a simple configuration and continuous process control.

To keep a flexible production running, the product specific gripper can be exchanged automatically and stored at the gripper bank. The support plate, which is mounted above the anvil is supplied with a manual fast exchange system.

As option a fiducial check can be done with a camera system to correct the insertion position regarding to the panel position and orientation.

• Feeder interface for basic feeding system

• Linear motors and NC- C Axis

• Support lift unit for minimized stress on PCB during insertion process

• Way/Force measurement

• Automatic tool exchange

• Intuitive and user friendly HMI (TS1)

Options

• Walking beam infeed

• Dual infeed conveyor

• Vision program for placement alignment

• 1D / 2D Code Reader

• Tool magazine for 4 grippers

• Automatic position correction with fiducial measurement

Catalogs

No catalogs are available for this product.

See all of IPTE Factory Automation n.v.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.