- Production Machines

- Forming Machine

- Hydraulic press

- MGI Digital Graphic Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

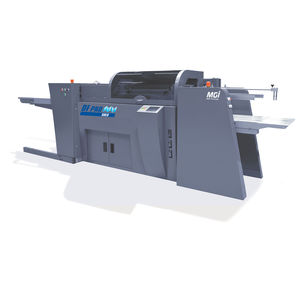

Hydraulic press PressCard Prolaminationcompacthot

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- lamination

- Structure

- compact

- Other characteristics

- hot, water-cooled

- Applications

- for plastics

Description

The PressCard Pro is an industrial production unit dedicated to the short run lamination of plastic substrates such as PVC, Vinyl, Synthetic Papers, etc...

The unique technology integrated in PressCard® range includes individual heating, cooling and pressure control circuits for the manufacture of Plastic Cards (ISO CR-80) from 200 microns up to 1000 microns for POP, Labels, Signage, etc.

These compact and professional hot lamination presses are fully automated and operate with a fast cycle.

Plastic Card Production

Process :

Standard lamination is done with one or two PVC sheets and an overlay protective film. Single stack and heat, auto water cooled process.

Speed :

Up to 2,400 cards per hour at 250-300 µ

Up to 2,000+ cards per hour at 760 µ (ISO CR-80 cards)

Sheet sizes :

Up to 330 x 482 mm, or 13” x 19”

Consumable Film : Clear PVC or P.E.T Overlay, Polishgard spacer for split core.

Inox lamination plate and pads.

Loading : 3 drawers of 10 stainless steel plates each, for a total of 30 sandwiches of 760 µ up to 860 µ (32 mils)

ISO CR-80 Templates : Cards on a 21-up layout for standard ISO Cards on a 13" x 19" sheet (330 x 482 mm)

Maximum Pressure :

Max. hydraulic pressure of 120 bars or 1740 PSI

Water cooling (water in / water out)

Weight : Approximately 1200 Kg

Dimensions : (L x W x H):

950 x 800 x 1610 mm

Electrical Requirements : 3 phases of 400 Volts - 32 Amps

Electrical power: 20 kW

Catalogs

Other MGI Digital Graphic Technology products

Digital Finishing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.