- Materials - Tools - Components

- Semi-finished products

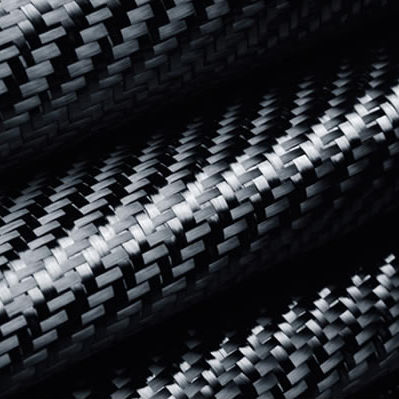

- Carbon fiber prepreg

- Mitsubishi Chemical Carbon Fiber and Composite GmbH

Carbon fiber prepreg 4550epoxytooling

Add to favorites

Compare this product

Characteristics

- Fabric type

- carbon fiber

- Resin type

- epoxy

- Other characteristics

- tooling

Description

Due to 4550’s high Tg and excellent mechanical properties, typical applications for 4550

include primary and secondary aircraft structures and areas where hot/wet performance

and impact resistance are important (i.e. fuselage skins, engine nacelles, wing spars and

skins, etc.) This material can be used to manufacture high temperature tooling,

providing extended tool life when compared to standard epoxy options.

4550 can be supplied with most commercially available fibers (carbon, quartz, aramid,

S-glass, E-glass, etc.) in both woven, unidirectional tape, and hot melt tow.

Woven fabrics are available in standard commercial widths up to 50 inches (1.2m).

Unitape widths up to 50 inches (1.2m) are available in standard fiber weights ranging

from 70–300gsm (0.014–0.060psf).

Recommended autoclave cure cycle

Apply full vacuum and 100psi (690 kPa), ramp with 3°F/min (1.7°C/min), step cure for 45

min at 250°F (121°C), then cure for 6 hours at 375°F (190°C), cool to <140°F (60°C),

followed by free-standing post cure at 410-460°F (210-238°C) for 6 hours. Cool to RT

before removal.

Alternate cure cycles available depending on final Tg

requirements.

Specific step cures may be necessary where flow management is important.

Catalogs

No catalogs are available for this product.

See all of Mitsubishi Chemical Carbon Fiber and Composite GmbH‘s catalogsOther Mitsubishi Chemical Carbon Fiber and Composite GmbH products

Prepreg

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.