- Robotics - Automation - Industrial IT

- Industrial Software

- Analysis software

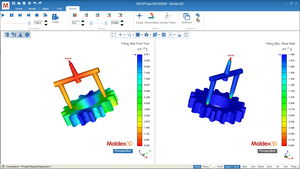

- Moldex3D, CoreTech System Co., Ltd.

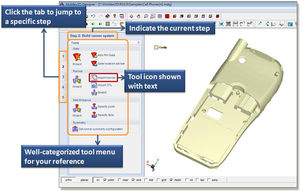

Analysis software Flowprocessflow3D

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- analysis

- Applications

- process, flow

- Type

- 3D

Description

Flow

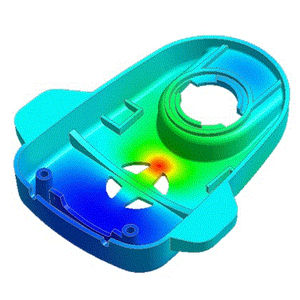

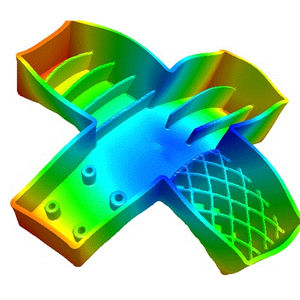

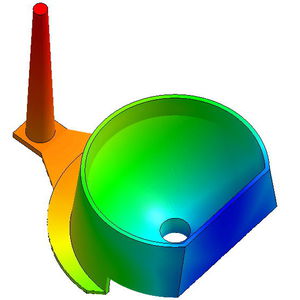

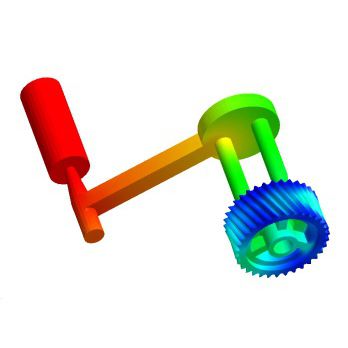

Moldex3D Flow explicit analysis capabilities give you deep insight in plastic flow behaviors from macro view to micro view, such as fountain flow, inertia effect and gravity effect. With the power of Moldex3D Flow, you can clearly observe melt flow behavior, accurately detect potential weldline and detect short shot problems, etc.

Capabilities

Predict 3D fountain flow phenomena, inertia phenomena, viscosity heating effects, etc

Predict weld line / air trap locations to minimize or eliminate

Predict the injection pressure and evaluate the requirement of clamping force

Evaluate the runner layout and type to minimize the volume of material and achieve runner balancing

Optimize the gate location and size to minimize weld lines and achieve balanced filling

Optimize process conditions in filling stage, such as injection time, melt temperature, ram speed profile, etc

Simulate filling process for multi-cavity molds or family molds

Simulate multi-component molding process, including insert molding and multi-shot sequential molding (Moldex3D MCM module is required)

Features

Surface defect Prediction

Weld line prediction

Air trap prediction

Molding defect diagnosis such for hesitation or race-tracking

Venting, Gate location (wizard)

Verify venting design with filling pattern

Initial air pressure can be specified

Quickly single/multiple gate locations recommendation

Constrain gating region of non-gating or gating can be specified

Cold & Hot Runner

Runner balancing prediction

Shear heating prediction

Sequential valve gate control consideration

Catalogs

Other Moldex3D, CoreTech System Co., Ltd. products

eDesign

Related Searches

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Online software

- Design software solution

- 3D software solution

- Simulation software

- Visualization software solution

- Creation software

- Optimization software solution

- Modeling software

- Calculation software

- Internet-based software

- Flow software

- Verification software

- Data exchange software solution

- 2D/3D software

- Viewer software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.