Stripping machine CT20

Add to favorites

Compare this product

Description

CT20 ultra-fast decoating unit (patented)

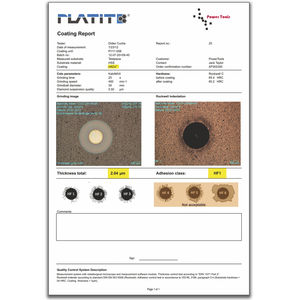

CT decoating systems from PLATIT set new standards in decoating, especially for carbide tools. The problem of cobalt leaching is circumvented by protecting the substrate with a TiN adhesion layer as the decoating process of the CT systems will not attack the TiN layer. For the CT20, the decoating cycle all the way to the TiN adhesion layer will take less than three minutes. The end of the process is automatically detected by built-in electronics. The adhesion layer is not removed and therefore "overcoated" after regrinding and pretreatment. A service life comparable to that of a new tool is achieved.

The new environmentally friendly wet chemical carbide decoating unit from PLATIT

Fastest decoating process worldwide

Decoating time is less than 3 minutes all the way to the TiN adhesion layer and the decoating cycle stops automatically at the TiN adhesion layer

A single recipe for a wide variety of nitride coatings with a TiN adhesion layer, independent of tool size

Multiple coatings can be removed as well

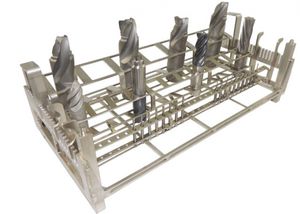

Special holders for shank tools, hobs, inserts etc. to avoid attacking uncoated areas

Max. tool dimensions: ø 200 x 250 mm

Cobalt leaching occurs only at the wear points

Common chemicals available worldwide

The process takes place at room temperature, neither heating nor cooling is required

The end of the process will be automatically detected, which greatly simplifies the operator’s work

Catalogs

Complete Solutions in Demand

6 Pages

Compendium

140 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.