SLA is our most detailed method. Using a UV light to selectively cure a light-sensitive resin, we can produce parts with details as small as some tenths of a millimeter with a range of different properties.

Technology Overview

By using a liquid resin, selectively hardened by a UV light projected from a DLP projector, we are able to reproduce details as small as a few tenths of a millimeter, or just a couple of pixels wide.

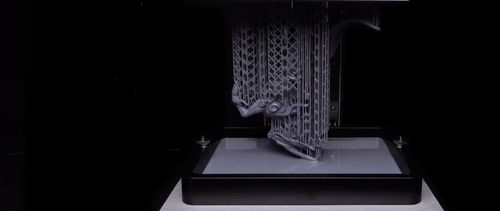

As almost all SLA parts require support material to build properly, each part submitted to us will be manually reviewed by an experienced engineer who will place the optimal support in order to reduce the markings from the support material onto your part.

All parts are supplied washed, post-cured and free of support material.

With our SLA equipment we can build parts up to 240x168x160 mm. Thanks to the mSLA technology where a full layer is exposed at the same time a print with one copy of your part will be produced in the same time as a full platform worth of parts.

Do you need something even larger produced? We are also able to split your part into smaller pieces to be assembled after printing, before the model is dispatched to you.