- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

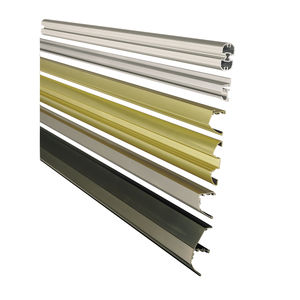

Electrolytic nickel plating electrolesssteelcopper

Add to favorites

Compare this product

Characteristics

- Type

- electrolytic, electroless

- Substrate

- steel, copper, aluminum, stainless steel, brass, zinc

Description

High-gloss and semi-gloss nickel plating

For many technical items one of the two above types of nickel plating is preferential to chromium plating for one or more of the following reasons:

In particular in parts with a complicated shape, chromium plating, which does not disperse as well, often fails to reach all points so that the nickel layer underneath remains visible in the form of "yellow spots”.

If the parts must still be shaped after nickel plating, the ductile (malleable) semi-gloss nickel plating is usually chosen from the above two processes instead of the more brittle high-gloss nickel plating.

In dry interiors in particular the corrosion performance of nickel on steel or nonferrous metals is usually sufficient if the weak yellow shade is acceptable.

Furthermore, this process is cheaper because items, which are to be nickel-plated should permit closer contact (i.e. the simultaneous treatment of greater quantities per rack).

Catalogs

No catalogs are available for this product.

See all of Rohde AG‘s catalogsRelated Searches

- Rohde anodizing

- Rohde aluminum anodizing

- Nickel plating

- Rohde anodizing with coloring

- Electroless nickel plating

- Rohde small series anodizing

- Rohde large series anodizing

- Rohde medium series anodizing

- Rohde hard anodizing

- Zinc-plating

- Galvanizing

- Hot dip galvanizing

- Chrome plating

- Rohde medical anodizing

- Rohde titanium anodizing

- Rohde industrial anodizing

- Steel nickel plating

- Rohde individual anodizing

- Steel galvanizing

- Aluminum nickel plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.