- Products

- Catalogs

- News & Trends

- Exhibitions

Ultrasonic welding machine automaticstandalonefor plastics

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Technique

- ultrasonic

- Operational mode

- automatic

- Configuration

- standalone

- Applications

- for plastics

- Other characteristics

- compact

Description

Thanks to its in-depth knowledge of plastics, S2E can integrate a welding function into your special machines: while heat welding enables you to weld close to sensitive parts (such as fiber optics), ultrasonic welding is faster, more reliable and requires little maintenance.

This welding function can be :

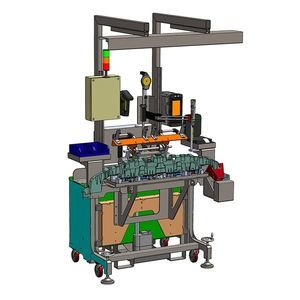

• a dedicated machine (with a compact welding unit for a good price/performance ratio);

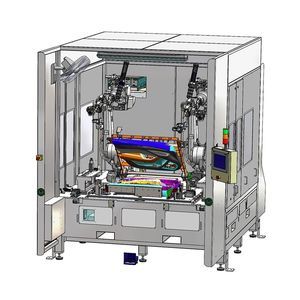

• a cassette machine (again, with a compact, flexible unit enabling rapid tool changes for multiple projects and parts);

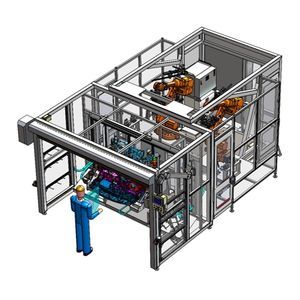

• a robotized welding cell (suitable for small and medium production volumes, reducing the cost of ultrasonic equipment while remaining flexible).

Ultrasonic generators from 20 to 40 Khz are adapted to customer requirements (design, cycle time, etc.). S2E integrates equipment from leading suppliers: Branson, Dukane, Mécasonic…

The advantages of ultrasonic welding

The right solution for your needs

From dedicated machines to double-head welding units with adjustable center distances, S2E can meet all your needs.

Test bench available from S2E

The use of a test bench helps to reduce project costs and fine-tune tools.

Design for production

S2E can adapt the design to the technology applied, thanks to early-phase work with the customer.

Welding fixtures

The materials and design chosen for our fixtures are adapted to the numerical definitions of the customer’s parts, as well as to their raw materials.

Fast, clean and sustainable

With no material input, ultrasonic welding is economical for large production runs, and generates no fumes or waste.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.