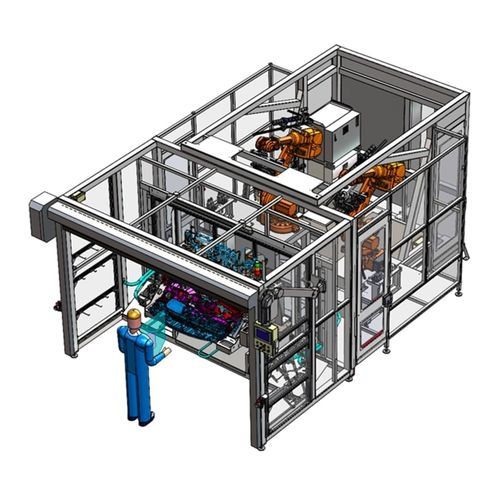

S2E integrates 6-axis robots for part handling, vision control, assembly and ultrasonic welding operations.

Our knowledge of Fanuc, ABB and KUKA enables us to meet most automotive OEM requirements.

We study the technical and economic feasibility of your project and validate cycle times, access, permissible loads… to offer you optimal solutions.

We also offer 3D simulations with RobotStudio (ABB) or RoboGuide (Fanuc) to clear up any technical doubts prior to production.

We can offer you flexible cells adapted to your needs, with quick-change multi-tools enabling you to switch from one type of part to another in just a few minutes. These solutions are ideal for the production of multi-version parts, where the utilization rate of the robotic island is optimized with the use of simple tooling.

The benefits of robotics

Precision and Quality

Robotics offer unrivalled precision in the handling and assembly of parts, guaranteeing consistent quality and reducing production errors.

Flexibility and adaptability

Robots can be quickly reprogrammed to adapt to different processes or parts, offering essential flexibility in a constantly changing production environment.

Productivity and Efficiency

Integrating robotics into special machines significantly increases productivity, enabling continuous operations and reducing downtime.

Safety and Ergonomics

Robots take on repetitive or hazardous tasks, improving operator safety and working conditions.

Medium-term profitability

The use of robotics translates into medium-term savings thanks to more efficient production and lower labor costs.