- Production Machines

- Other Manufacturing Equipment

- Hammer mill

- Shanghai Clirik Machinery

- Products

- Catalogs

- News & Trends

- Exhibitions

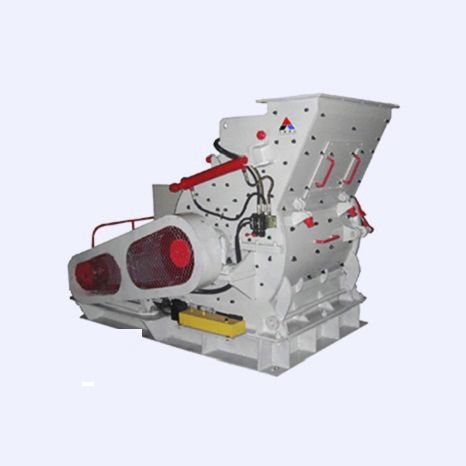

Hammer mill PC40 seriesverticalglasscoarse powder

Add to favorites

Compare this product

Characteristics

- Technology

- hammer

- Orientation

- vertical

- Product applications

- glass, coarse powder, stone

- Other characteristics

- high-speed

- Rotational speed

Min.: 550 rpm

(3,456 rad.min-1)Max.: 1,000 rpm

(6,283 rad.min-1)- Output

Min.: 10 t/h

(6 lb/s)Max.: 100 t/h

(61 lb/s)- Motor power

55 kW, 75 kW, 90 kW

(74.78 hp, 101.97 hp, 122.37 hp)- Machine length

2,310 mm, 2,840 mm, 3,720 mm

(91 in, 112 in, 146 in)- Machine width

1,665 mm, 2,100 mm, 2,650 mm

(66 in, 83 in, 104 in)- Machine height

1,610 mm, 2,020 mm, 2,540 mm

(63 in, 80 in, 100 in)

Description

Coarse powder hammer mill is engaging in crushing various rocks and stones(such as Limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, manganese ore, quartz, active carbon,glass ect) with comprehensive strength not higher than 320 MPa into coarse powder and small particles, it is widely used in metallurgy, mining, chemical, cement, coal, sand-making, coal gangue, construction, refractory materials and ceramic industries.

Coarse Powder hammer Mill mainly consists of frame, rotor, support iron and grate bars. The frame is divides into two parts: upper part and low part, which are welded by steel plates after being cut. Liners made of high manganese steels within the frame can be replaced after being worn out. The rotors consist of turnplates, pin shafts, and hammers which are grouped regularly in the main shaft. The main unit drives the main shaft through the motor and triangle belts, which, in turn, rotates the rollers. Large materials entering the crusher through the feed inlet are firstly crushed by the high-speed hammers, and the thrown fiercely to the support iron for further crushing. Qualified materials crushed will be screened out and exit from the gap of the grate bars while the unqualified will be left in the crushing cavity to be further hammered and ground until reach the standard size. The size of the final product can be adjusted by changing the grate bars. The gap between the rotors and the grate bars can also be adjusted according to different requirement. To avoid the plugging of the crusher, the proportion of water for the crushing material is no more than 20%.

Related Searches

- Grinding mill

- Vertical grinding mill

- Rotor lump breaker

- Impact grinding mill

- Roller grinding mill

- Building materials grinding mill

- Mill for the pharmaceutical industry

- Mineral mill

- Hammer grinding mill

- Powder grinding mill

- Rotary drum grinding mill

- Ball grinding mill

- High-speed pulverizer

- Metal mill

- Stone grinding mill

- Ultrafine grinding mill

- Large grinding mill

- Glass grinding mill

- Cement grinding mill

- High-pressure grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.