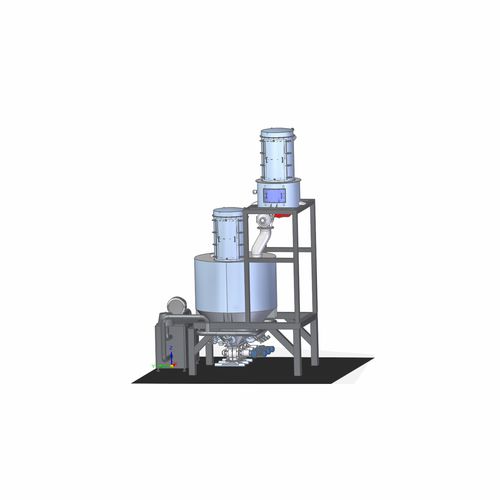

Powder cooling system for the food industryair-cooledhigh-pressure

Add to favorites

Compare this product

Characteristics

- Material

- powder

- Applications

- for the food industry

- Other characteristics

- air-cooled, high-pressure, condensation

- Maximum temperature

16 °C

(61 °F)

Description

•Ranges from 30°C in the silo to 14°C in the mixer.

•Guarantees even temperature of dough throughout the year.

•Avoids adding ice.

•Improves mixing.

•Low operating costs without the need for CO2.

APPLICATIONS

Maintains a uniform mix temperature and avoids the need to add ice in automated operations. Cools the flour supplied by silos and regulates temperature according to programmable settings.

OPERATION

The flour is mixed with cold air in a hopper located between the storage silos and the flour distribution station.

The cold air is generated by a heat exchanger and circulates continuously in the bin through a high-pressure fan and fluidizing bed. The hopper is insulated and jacketed to ensure optimal cooling and avoid condensation.

The air is perfectly homogenized with the flour to ensure a consistently uniform temperature. A temperature probe controls both the flour temperature and the heat exchanger until the desired temperature is reached.

TECHNICAL DATA

•Capacity from 1 to 2 t./h. per unit.

• Cooling up to 16°C from the initial temperature (Δ T 16°C).

Catalogs

No catalogs are available for this product.

See all of TECHNOSILOS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.