- Building - Construction

- Construction and Mining Equipment

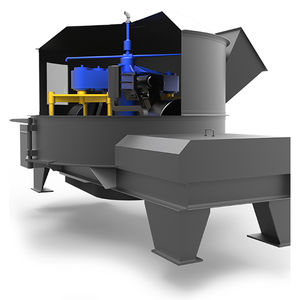

- Roller crusher

- Titan Machinery LP

Roller crusher stationary

Add to favorites

Compare this product

Characteristics

- Technology

- roller

- Mobility

- stationary

Description

Use of Crushers for Additional Crushing of Screenings (Stone Breaking Waste Products)

Our equipment uses rock screenings as raw material very often. Rock screenings are stone breaking waste products. The point is the 0—10 mm (or 0—5 mm) fraction meets very little use and therefore becomes accumulated in waste piles in very large quantities. Such fraction is an excellent raw material for our presses (and other equipment) but it requires additional crushing, usually up to the fraction of 0—3 mm.

For crushing of such raw material up to the fraction of 0—2 (0—3) mm, some types of crushers can be successfully used:

Roll crusher

Hammer crusher

The roll crusher is more preferable to this end because of the lesser maintenance work. Rolls made of high-quality steel guarantee the reliability of the crusher without maintenance over the time of 12 months or more.

The hammer crusher is very simple and cheap but it requires rather frequent replacement of hammers (steel plates). For example, even when crushing lime it is required to replace hammer kit every 2 or 3 weeks.

Both of the crushers are sensitive to the excessive humidity of raw material.

Catalogs

No catalogs are available for this product.

See all of Titan Machinery LP‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.