- Industrial machines and equipment

- Welding and Assembly

- Automatic assembly machine

- Wuxi Novo Automation Technology Corporation

- Products

- Catalogs

- News & Trends

- Exhibitions

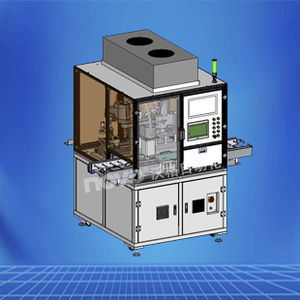

Automatic assembly machine LGPfor industrial applicationscompact

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for industrial applications

- Other characteristics

- compact

Description

This machine can automatically transfer and locate backlight plate, and load, clean, suck, locate, assemble, press and check LGP. It adopts visual location with scan function, and bind visual information with product together, and be with one-key changeover function.

Boundary Dimension: L1800mm, W1700mm (excluding unloading transfer arm), H2050mm (excluding tower lamp, FFU)

Weight: 1200kg

Power Supply: AC220V, 5KW

Air Supply:0.5~0.7MPa,≥300L/min

CT: 11s

Assembly Precision: ±0.05mm (repetition precision for the same product)

Product Specification:10.1~15.6 Inch

LGP Load Thickness: 300mm

•CCD Visual System: Hikvision CCD, Cognex Vision Pro Software

•Robot: Inovance

IPC:ADLINK

PLC:OMRON

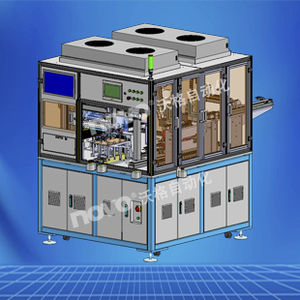

Batch loading of LGP, with long change period and short loading time;

LGP and backlight plate adopt CCD visual location with high precision;

Adopt 6-axis transfer arm to assemble LGP with flexibility and fast speed;

Design based on dust-free high standard to ensure the control of internal clean class and yield. The clean class is up to a thousand level;

Be equipped with scan function. It can bind data from visual location and product and be traced to ensure yield;

Be equipped with one-key changeover function. That is to say, it can switch to different LGPs quickly;

Production data within 30 days can be saved, and can be connected to MES system.

Other Wuxi Novo Automation Technology Corporation products

Flat Panel Display Equipment

Related Searches

- Welding system

- Automatic welding system

- Laser welding system

- Precision welding system

- Mounting machine

- Automatic mounting machine

- Assembly line

- Automated assembly line

- Assembly machine for industrial applications

- Compact assembling machine

- 4-axis welding system

- Clinching machine

- Plate assembly machine

- Automatic clinching machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.