- Hydraulics - Pneumatics

- Pump

- Gas pump

- FLOWSERVE

- Products

- Catalogs

- News & Trends

- Exhibitions

Reciprocating pump Vfor chemicalsslurryoil

Add to favorites

Compare this product

Characteristics

- Fluid

- for chemicals, slurry, oil, for gas

- Technology

- reciprocating

- Mobility

- stationary

- Domain

- industrial, for wastewater treatment, for the pharmaceutical industry, for the mining industry, for the nuclear industry

- Applications

- high-pressure, lubrication, high-temperature, replacement

- Other characteristics

- suction, mechanical, standard, high-efficiency, triplex, vertical, quintuplex

- Flow

1,140 m³/h

(40,258.72006 ft³/h)- Pressure

621 bar

(9,006.844 psi)- Power

Max.: 3,470 kW

(4,717.89 hp)Min.: 56 kW

(76.14 hp)- Fluid temperature

Max.: 288 °C

(550.4 °F)Min.: -40 °C

(-40 °F)

Description

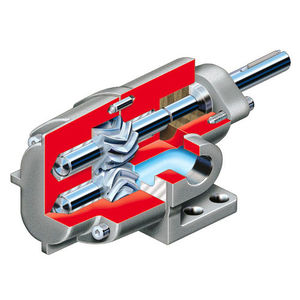

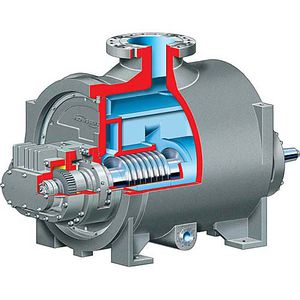

The V pumps include vertical triplex, quintuplex, septuplex, and nonoplex positive displacement reciprocating pumps with very high efficiency and are offered in a wide range of hydraulic, mechanical, and material options.

Sectionalised liquid ends suitable for heavy duty oil & gas applications

Self-aligning plungers ensure proper concentricity within stuffing boxes

Many valve styles to suit all liquid types from clean liquids to hard slurries

Stuffing boxes outboard of cylinder allowing for more complex sealing and piping arrangements

Stuffing boxes individually fastened to liquid cylinder for ease of maintenance

Totally enclosed power frame is dust and oil tight eliminating atmospheric contamination

Cylindrical crossheads and guides maximize the load bearing area and reduce wear, keeping replacement costs to a minimum

Various bearing lubrication systems from splash to full pressure

Size Range: From 76.2 mm (3.00") to 228.6 mm (9.00") stroke, with 12.7 mm (0.50") to 228.6 mm (9.00") diameter plungers, with power ratings of 56 kW to 3470 kW.

Standard Design

Sectionalised liquid end with multi-cylinder or individual cylinder arrangement and separate manifolds, clean liquid valves, and full pressure bearing lubrication

High Suction Pressure Design

Special crosshead pin bearings and lubrication system to cope with non-unloading of that bearing

High Liquid Temperature Design

Individual cylinders and special manifold fastening arrangement to cope with thermal expansion effects on plunger centre distance

Slurry Design

Special liquid end arrangement for constant velocity flow, stuffing box flushing, and slurry valves to cope with solids in the liquid

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Flowserve pump

- Flowserve industrial pump

- Flowserve stationary pump

- Flowserve water pump

- Flowserve centrifugal pump

- Flowserve chemical pump

- Flowserve stainless steel pump

- Flowserve lubricant pump

- Flowserve pump for the chemical industry

- Submersible pump

- Flowserve compact pump

- Flowserve oil pump

- Suction pump

- Impeller pump

- Mechanically-actuated pump

- Flow pump

- Top-mounted pump

- Discharge pump

- Flowserve handling pump

- Standard pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.