- Industrial machines and equipment >

- Surface Treatment >

- Anodizing

Anodizing

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Anodising is used to produce protective and decorative oxide layers on aluminium, improving corrosion protection and wear resistance. Different colours are created by dyeing or electrolytic colouring. Benefits -Long life time and ...

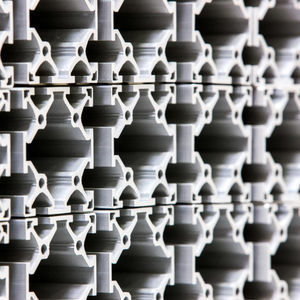

CNC processed profiles, black anodized, mainly used in housings in various electronic fields.

HLC METAL PARTS LTD

Custom CNC Parts Manufacturing refers to the process of using Computer Numerical Control (CNC) machines to produce custom-designed parts. This process involves the use of software programs that are specifically designed to control the ...

HLC METAL PARTS LTD

These are custom parts from our European customers. 4-axis cnc machining with black anodized surface. If you have any needs, please contact us.

HLC METAL PARTS LTD

Surface finishing using the anodising process In anodising, we place particular emphasis on occupational safety, environmental protection and quality. Our well-trained team and modern technology ensure that these requirements are ...

KERBIRIO

KERBIRIO

KERBIRIO

EXTOL has a modern and technologically advanced 48,000 ampere anodising plant. This plant is fully automated and has a capacity of 6000 bars per day. It can accommodate profiles up to 7.2 metres long. This type of finish hardens ...

In contrast to the conventional galvanising process, no foreign metallic cover layer is applied during anodising. Instead, the surface of a light metal component is converted into an oxide layer by the galvanising/anodising process. Since ...

Collini Holding AG

In contrast to the conventional galvanising process, no foreign metallic cover layer is applied during anodising. Instead, the surface of a light metal component is converted into an oxide layer by the galvanising/anodising process. Since ...

Collini Holding AG

In contrast to the conventional galvanising process, no foreign metallic cover layer is applied during anodising. Instead, the surface of a light metal component is converted into an oxide layer by the galvanising/anodising process. Since ...

Collini Holding AG

... generator (amperage, voltage, current quantity) are modified according to each treatment. A cathode device will be used during anodizing on aluminum or titanium alloys An anodic tool* is composed of 3 inseparable parts ...

DALIC

... generator (amperage, voltage, current quantity) are modified according to each treatment. A cathode device will be used during anodizing on aluminum or titanium alloys An anodic tool* is composed of 3 inseparable parts ...

DALIC

... generator (amperage, voltage, current quantity) are modified according to each treatment. A cathode device will be used during anodizing on aluminum or titanium alloys An anodic tool* is composed of 3 inseparable parts ...

DALIC

The selectron process, colloquially known as tampon plating, is a special galvanic process by which layers are partially deposited. Selectron is particularly suitable for repairing minor damages to specific areas. The optimal repair ...

Surface treatment: an essential step in the production of mechanical parts On the strength of its expertise in machining , Figeac Aero has also branched out into the field of "surface treatment" for the finishing of metal parts. In ...

Figeac Aero

Your concerns drive our daily work. If you are looking for solutions to optimise your costs, increase the reliability and quality of your products, or develop your capacity, HACER is at your service and available to work together and ...

Bright Dip anodizing enhances the glossy appearance of aluminum for cosmetic applications and achieves a highly reflective surface finish similar to mechanical polishing. In contrast to plating, Bright Dip is a chemical ...

Pioneer Metal Finishing

SURFACE TREATMENT Five different lines for protection and surface treatment of the light alloys (Aluminium, Magnesium) or hard materials (steels, Titanium, Inconels...). - Aluminium and Aluminium alloys (Chromatation, CAA, ...

BONNANS

1. Finish: Anodize, Alumite ,Powder Coating 2. Tolerance: +/-0.004mm 3. OEM Service 4.Minimum Order Quantity:Small quantity acceptable 5.Payment Term:T/T. L/C. 6.Lead time:30 ~ 45 days 7.Packing:Standard export carton or based on ...

NANKAI

Experienced companies that are closely associated with Glüpker Blechtechnologie and share our philosophy carry out industrial coating using different processes. Thanks to the great flexibility and quality of the individual procedures, ...

Glüpker Blechtechnologie GmbH

OX-HS is a hard anodizing treatment of aluminium in sulphuric acid in compliance with MIL-A-8625 Type III, ISO 10074, and UNI 7796 standards. The OX-HS hard anodizing process transforms the aluminium ...

Micron Srl

Medical robot parts Material: aluminium 7075. Surface treatment: anodised blue. Anodising of aluminium is an electrolytic oxidation process in which the surface of aluminium and aluminium alloys is usually transformed into an ...

AbleMed

... We can also supply surface treatment methods, such as painting, silk screening, pad printing, polishing, sand blasting, anodizing, powder coating, plating, passivation, laser etching and knurling etc. If you have ...

Anodised products are in accordance with Qualanod norms. We are able to achieve different anodising thicknesses and colors from 5 to 25 microns. We offer following surface finishes; Anodising Mechanical Polishing Semi-Gloss High ...

ANODIZING - SURFACE TREATMENT OF ALUMINIUM Mekoprint has extensive expertise in development, production and surface treatment of aluminium with anodizing. Therefore, we can advise and offer ourselves ...

... quality goods to our customers. Anodizing is an electrochemical process that converts the metal substrate surface into a durable, corrosion-resistant, attractive anodic oxide finish. Aluminum is ideally suited to anodizing, ...

Applied Total Control Treatment Pte Ltd

... , Lenso Aerospace expanded their in-house expertise to provide anodizing and passivation to the Aerospace industry. Starting in Q4 2016, Lenso Aerospace will bring in-house clear anodizing, brush finishing ...

The bright anodic oxidation is a process of electrolytic conversion of aluminium metal covered by an oxide layer which grows as an integral part of the metal itself, obtained by acid solutions with specific additives, ...

SILGA

AÉROPROTEC specializes in the surface treatment and painting of metal and composite material parts used in the aeronautical industry, essentially to protect them against corrosion according as per specifications from customers such as ...

AERO PROTEC

The BF5 process is covered by a patent and a trademark registered by SGI; it is a chromic anodizing process which is characterized by its simplicity and reliability of use. -It forms a low thickness oxide film (2 to ...

SGI - Société de Galvanoplastie Industrielle

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining