- Machine-tools >

- Machine Tool Accessory >

- Automated loading system

Automated loading systems

... grippers With the great selection of a wide variety of gripper types, almost every EROWA tooling system can be handled. Helpful position display The display (option) enables the ...

... Carriage can be also equipped with a totally automatic loading system from the melting furnace, which carries three ladles to the casting carriage, so that it guaranees always the continuity ...

Addressing specific tray-positioning requirements or the unique demands of the loading process, our engineering team has cultivated expertise over several years through collaborative design efforts with clients, developing ...

... chain drive system incorporating the pneumatically activated rise and fall chain and roller track. Moves pre-assembled loads up to 30 tonnes from the dock to the trailer in 90 seconds. The slipchain supplies high-speed ...

It is a equipment that moves a basket from a conveyor to a handcar or from a handcar to a conveyor. Feature . Process capability 10,000 bottle(625basket/h) . Process height 170 ~2310mm . Equipment size 1090(W)×3000(H)×940(L) ...

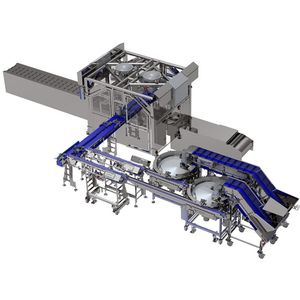

Automated system of loading packaged products to crates to reduce manual handling. Products are loaded according to the pre-set patterns. 2700 pcs. per hour 24/7 continuous operation • ...

... • Inserts: format sets, portions, individual slices or pieces Description The compact SmartLoader is a fully automatic side loading system for single products or individual portions. ...

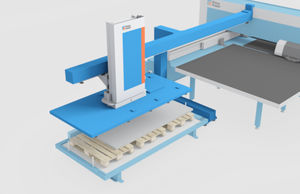

The loading station is used on solid forming presses to ensure the feed of the parts before transferring with the transfer system. The loading system aligns or straightens ...

... inside rope and dustproof docking system (optional). • Fail-safe due to the electro-pneumatic installation, level sensor, limit switches and complete control unit (options) • Less operating costs ...

HOSOKAWA SOLIDS, S.L.

Highly flexible and versatile machine – Load all types of sausages: soft, brittle, flexible, steef, peeled or skined – Load in all directions: parallel and perpendicular – Load all packing configuration: single or multiple layers, ...

... safe charging process Make sure you make the very most of the VA-L’s performance potential: Using a material feed system configured ideally to the sawing process, you can maximize your sawing output. Our approach ...

The innovative “Easy-Load” system allows the automatic loading of the cardboard blanks magazine and features considerable advantages from an operating and functional point of view; in ...

... molding and enrobing systems. No matter whether they’re round or rectangular and upright, flat, or shingled. But with high performance, gently on the product, and efficiently. And, depending on requirements, all in the ...

... transfer, alignment, buffering, and loading - one solution The MULTIVAC Belt Loader systems range is flexible, space-saving, and offers you a wide range of versions. Whether manual ...

The Gadda group produces 4 axis Automatic Loading Machines that are designed to: – Move loads up to 50 T along the batch line – Immerse loads in the quenching tank – Withdraw and deposit loads onto ...

Loading system for plastic wet wipe containers and lids. The first operator positions the container on the fed pile of wetwipes. The container is turned upsidedown and the second operator can apply ...

As material loading is an integral part of every production process, minimal disruption of material flow with complete control is essential. TSM offers a range of reliable and user friendly Stand Alone ...

•Loading profiles in automatic mode •Between 10-12 profiles depending on the type of profile •Adjustable loading speed •Adaptable to GAA model machines with CNC controller already installed •Safety ...

AUTOMATIC OR MANUAL LOADING The parallel loading belt system optimises the boxing process, allowing the choice of automatic or manual loading ...

... that does not damage delicate products. HIGH PRODUCTION AUTOMATION FOR LOADING THERMOFORMS Modular system. High-output machines with 1 to 3 in-line collectors. High loading capacity ...

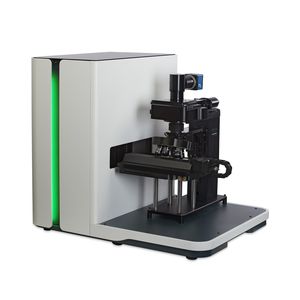

The MS 1 is an automatic orientator capable of quickly aligning batches of 150 or 300 capsules at a time. This machine is best used in combination with one or more semi-automatic capsule-filling machines such as models ...

• Available for following automatic cutting machines: Profilma 250, 500 E, 510 E, 600 R • Top loading by crane or fork lift • Max. bundle Ø 650 mm • Max. load 4.000 kg • Bar length 3.000 – 6.200 mm • ...

• Chain conveyor for heavy profiles • Available for following automatic cutting machines • Max. load 5.300 KG • Dimension of stories fix, e.g. max. cutting range of the saw • Conveying length 1.550 ...

• Tooth belt drive with profile slide • Available for following automatic cutting machines • Max. load 750 KG • Dimension of stories fix, e.g. max. cutting range of the saw • Conveying length 1.850 ...

Automated machine loading with a cobot provides unique benefits for companies. That's why KUKA partnered with the technology and automation developer MAIROTEC to create a modular automation cell that ...

... of different loading tables and wagons CAPACIT Large loading scope AUTOMATION Possibility to connect to automated storages COMBINE Connection to cut-to-length line Overview Loading ...

... OEMs and system integrators and allow for precise and safe loading of slides for the pathology, cytology, and screening markets. Prior Scientific designed this system from the ground ...

Prior Scientific

... . To accommodate higher quality control demands, additional inspection options can be added to the systems (hole and crack recognition, surface measurement, lifetime and resistance measurement). Quality ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining