- Machine-tools >

- Machine Tool Accessory >

- Automatic feeding system

Automatic feeding systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... without problems. Strong performance The basis for the constant and high feeding capacity is the combination of vacuum and dense flow feeding. Flexible applications Feeding ...

... wire racks • - Integrated wire end detection with automatic stop • - Machine wire line at optimal working height for the operator • - Speed of up to 6 m/s can be adjusted directly on the prefeeder The ...

The PreFeeder 2200 is a free-standing, electrical prefeeding machine designed to pull wire and cable from reels weighing up to 70 kg (154 lbs.).

With the LID MASTER and LID SERVER, NSM offers modular systems that can be individually adapted. In combination with buffer magazines and transport systems, we can feed and distribute ...

... contamination. 2- Automated addressing of the feed of the machine or silo, avoiding waste by cross contamination of PVC compounds. 3- Inventory control from the mixer outlet to the ...

CAD/CAM feeding systems •Maximum system availability •Complete reproducibility •Cost benefits for repeat orders •Highly precise production with 5-axis simultaneous processing and ...

High speed gripper feeder, automatic feeding of 0.1-1.5mm materials (feeding speed up to 1200 times/min), suitable for high-speed punching with high-speed press punching machines, such ...

... high-precision feeding. 2. There is no need to adjust the feeding step distance, and the feeding distance can only be changed by gears. The change of feed distance ...

packaging machine for the food industry feeding systemLEKO series

Gripping module and Product infeed system for products which are supplied in rows. LEKO-EB – CONVEYOR FEED From the forming belt / cooling belt on the feed belt of e.g. a wrapping ...

CHOCOLATE BAR INFEED SYSTEM The Chocolate bar infeed system LEKO-RET has been developed for the continuous feeding of a flow wrapping machine „in the smallest space“. The particularly ...

OFFLINE FEEDING SYSTEM • Filled plates / trays / transport plates / etc. are fed in batches • Plates are separated from the stack • Products are aligned on the plates • Products are removed in rows ...

The system is advanced in technology, safe and reliable, with high production efficiency, with automatic feeding and changing function. The whole suction cup has suction plate, which ...

... Transmission Distance Detection / Laser Sensor Die Memory System Multiple External Outputs Press Control Automation System Operating from Touchscreen Panel and Remote Tech Support Automatic ...

... Servo Feeding System, Which Moves in Two Axes (X And Y), Is Specifically Preferred for Minimum Waste at Perimeter/Flake Cutting Processes. Its Body Structure Design Enables to Easily Adapt to All Kinds ...

... , and ‘friction time’ between the bottle and the system - when the bottles come into contact with machine parts - is dramatically reduced (by at least 20 times) compared to an endless screw infeed system. In ...

... DM5 Dynapail’s™ standard features, which include field-interchangeable platen faces, self-diagnostics, multiple temperature control sensors, and low/empty drum indicators. Overview DM5 Dynapail Unique platen ...

Gluer Unit High-precision lead edge feeding system and multifaceted alignment system, ensure accurate cardboard feeding.

Designed to enhance performance and productivity, this servo-driven feed system works on both continuous and intermittent blister packaging lines. As all feeder adjustments are managed electronically ...

... in-line automatic infeed system This flowfeed infeed system tranfers products arriving in a single line to a continuous supply to the infeed chain of a flowwrapper. The flowfeed works ...

For optimum yield, combine your cutting machine with a fully automatic synchronisation in order to continuously feed your deep drawing machine. Capacity: up to 10 infeed cycles per minute.

Rockwool automatic transmission device used in all PLC to operate, stable and secure, adjustable speed, good speed, can greatly improve production efficiency rockwool products.

The Full Automatic Charging System will deliver the specified amount of the molten metal directly to the holding furnace which sent the “Low Metal” signal using a Ladle Cup. This method is not required ...

... these characteristics are essential for accurate control of product weight. A metal detector can be inserted into the system to prevent damage to the forming machines. Automatic operation Dough ...

Feeding cells and feeding systems – We are particularly proud of our versatile feeding technology SIM feeding and sorting systems ...

V-BELT CHARGING SYSTEM - VAA Glimek V-Belt Charging System for automatic charging of dough pieces on swing tray proofer or belt proofer.

Glimek

Characteristics Side feed applicator of a new generation, uses a special feeding system which, thanks to specially designed lever ratios, making it incredibly smooth and quiet use. It's ...

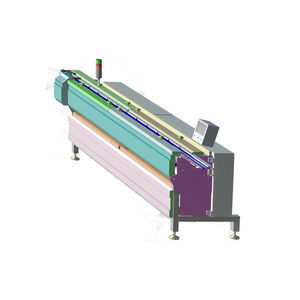

automatic feeding system3VRP15 / 3VRP18 / 3VRP22

... material - very low pressure load on material (max. 18 bar) - emptying of material with filler content - no backflow in the emptying pump - electrical control of pump with pressure ...

Product Type: Hot Melt Dispensing Equipment Automatic Adhesive Filling Systems Market Category: Packaging Installing an automatic feeder ensures a continuous workflow, eliminating ...

The Valco Melton Auto-feed vacuum system automatically administers adhesive into a connected hot melt tank, avoiding time loss and extra labor costs caused by typical manual refilling operations. The auto-feed system ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining