- Production Machines >

- Other Manufacturing Equipment >

- Coal grinding mill

Coal grinding mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Rotational speed: 3,000 rpm - 10,000 rpm

... Beater Mill SR 300 is suitable for coarse and fine size reduction, either in batches or continuously. It can process dry, soft, medium-hard, organic and inorganic substances. With its adjustable speed of 3,000 to 10,000 ...

The Retsch Disc Mill DM 200 is used for grinding medium-hard, hard and brittle materials. Thanks to its robust design it is suitable for usage under rough conditions in pilot plants and laboratories. ...

Rotational speed: 912 rpm

... simultaneously. This mill accepts grinding set weights of up to 30 kg, the largest grinding jar has a volume of 2,000 ml. The closed grinding system guarantees complete ...

Rotational speed: 800, 1,600 rpm

FRITSCH Planetary Ball Mills – high-performance all-rounder in routine laboratory work The Planetary Mill PULVERISETTE 5 premium line with 2 grinding stations is the ideal mill ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 300 rpm - 3,000 rpm

Output: 60 kg/h

... against cross-contamination. Unique grinding chamber geometry The sample material is comminuted according to the cutting principle of scissors between the cutting edges of the rotor and the fixed knives in the grinding ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 800 rpm

... OVERVIEW FRITSCH Planetary Ball Mills – high-performance all-rounder in routine laboratory work The Planetary Mill PULVERISETTE 5 premium line with 2 grinding stations is the ideal ...

Fritsch GmbH - Milling and Sizing

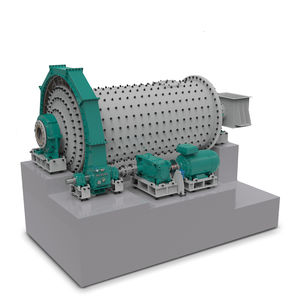

... most advanced technology in Mills using Grinding Media for micronizing. A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill. ...

Final grain size: 170 µm

Output: 10 t/h - 320 t/h

Motor power: 250, 220, 280, 185 kW

... ceramics. Learn More About Liming® LM Vertical Mill 1. Low Investment Cost. This mill itself can crush, dry, grinding, classifying, so the system is simple, and occupation area ...

Henan LIMING Heavy Industry Science and Technology

Final grain size: 1,600 µm

Rotational speed: 740 rpm - 990 rpm

Output: 4 t/h - 45 t/h

MTW Trapezium Mill Large capacity, Low consumption, Environmental friendly MTW European Trapezium Mill has a large market share in the grinding industry. Whether bevel gear overall ...

Henan LIMING Heavy Industry Science and Technology

Rotational speed: 1,480 rpm

Output: 3 t/h - 13 t/h

Motor power: 75, 37 kW

... speed downwards and prolong the grinding time for materials, thus the grinding efficiency is increased.; the pressing springs have the functions of balancing and pressure increasing; the flexible connection ...

Henan LIMING Heavy Industry Science and Technology

... Cutting Mill The hammer mill has the following features An exchangeable rotor with pendulum-suspended beaters or cutting knives, which can be replaced individually. -Easily removable grate basket or ...

Rotational speed: 6,000 rpm

Motor power: 2 kW

Machine weight: 68 kg

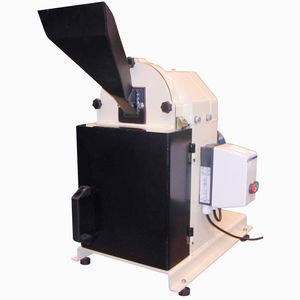

... 200 Lab Mill is used for crushing: Bricks Chemicals Coal Concrete Grain Ores & Minerals Soil Spices and many more materials in the medium hard range. Once the material is fed into the feed ...

Output: 150 kg/h - 200,000 kg/h

... project it between the roller and the ring where the grinding takes place. Air enters the mill though ports in the base under the grinding ring, and sweeps the fines and medium fines ...

The BRF dual-rotor universal mill is an evolution of the FNG universal mill. The BRF’s design is based on FORPLEX impact crushers (such as the FNG or FPX models) but is engineered with two oppositely ...

Output: 3 t/h - 83 t/h

... on-site test data for more than thirty years, SBM, a Chinese grinding mill manufacturer, has researched and developed the fifth-generation pendulous hanging grinding mill – MB5X grinding ...

Shibang Industry & Technology Group Co., Ltd.

Output: 3 t/h - 50 t/h

... European Grinding Mill is innovatively designed through deep research on grinding mills and development experience. It absorbs the latest European powder grinding ...

Shibang Industry & Technology Group Co., Ltd.

Output: 4 t/h - 300 t/h

... famous international corporations and 30 years’ experience in grinding mill production, SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, ...

Shibang Industry & Technology Group Co., Ltd.

Final grain size: 1 µm - 3,000 µm

Rotational speed: 600 rpm - 1,800 rpm

Output: 8 t/h - 30 t/h

Grinding at a medium fineness (0÷5 mm) of low and medium hardness minerals (gypsum, talc, lime, dolomite, clay, coal, etc); chemical products; scraps of brittle manufactured products (for example, waste ...

Final grain size: 40 µm - 300 µm

Output: 1,500 kg/h - 22,000 kg/h

Motor power: 45, 90 kW

... competitive cost with the introduction of hot gas through the mill. The ROLLER MILL can operate in closed circulation of inert gas, controlled by suitable safety equipment. In these conditions the Roller ...

... application a Vertimill® has 50% less footprint than a ball mill. Lower operating cost Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than for example ball ...

Final grain size: 75 µm

Output: 10 t/h - 40 t/h

... pulverized coal with capacities from 10 to 40 metric tons/hour. • Low-maintenance design a) Higher available grinding mass. b) Arrangement is such that most of the coal particles ...

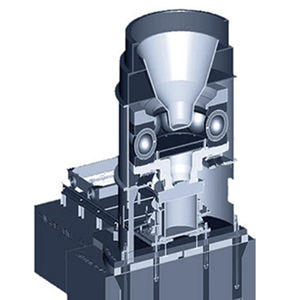

... mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw ...

Thanks to a bed material grinding concept, the vertical FCB E-mill offers power consumption reduced by 50% compared to the ball mill for coal grinding. Customer ...

Output: 500 kg/h - 400,000 kg/h

... are the grinding chamber and the agitator screw. The grinding chamber The vertical cylindrical grinding chamber is the heart of the TowerMill where comminution of mineral bearing ores ...

cement, coal-fired power, metallurgy & chemistry etc Suitable materials: Coal powder the air swept mill is suitable for coal grinding. When the ...

Output: 40, 100, 342, 500 t/h

... control and separation. The FAM product range includes impact mills, roller mills, hammer mills, ball mills and rod mills, as well as appropriate roller screens.

Output: 20 kg/h - 2,000 kg/h

Turbo Mill is different from other kinds of grinders. Raw materials will be ground via the force of cutting, impact, innumerable high speed vortex and high frequency vibratory. Not only the raw materials with tough flexibility ...

Final grain size: 10 µm - 20 µm

... Special soundproofed safety cabin. It is used in the grinding process of fragile materials and minerals such as basalt, bauxite, concrete, chrome, vanadium, dolomite, ferromanganese, ferrovanadium, granite, coal, ...

Output: 5 t/h - 70 t/h

Coal vertical mills also called coal mills, which are specialized in superfine grinding of raw coal and bituminous coal ...

Xinxiang Great Wall Machinery Co., Ltd

Rotational speed: 74 rpm - 167 rpm

Output: 0 t/h - 40 t/h

... processing, power plant desulfurization, non-metallic mineral pulverization, coal powder preparation, etc. Raymond Mill Raymond mill (Raymond roller mill) is applicable ...

Output: 400 kg/h - 22,000 kg/h

... Suspension Mill meets the requirement of national dust-dump standard. Working Principle General:Crushing -- Grinding -- Selecting -- Collecting Detailed:The High-pressure Suspension Mill ...

Shanghai Joyal Machinery Co., Ltd.

Motor power: 2 kW

Machine length: 520 mm

Machine width: 580 mm

5E Series Pulverizer is used to pulverize the sample after crushing in power plants, coal mines, chemical industry, metallurgy, building material and geology, in which an analysis sample of particulate ...

... Construction of rolling ball type mill (E type mill ) 1960's Production of plate type mill 1970's Manufacture of rolling ball type mill (ZQM series) 1980 Start to ...

BEIJING POWER EQUIPMENT GROUP CO LTD

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining