- Packing - Handling - Logistics >

- Conveying >

- Dense phase pneumatic conveying system

Dense phase pneumatic conveying systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

PNEUMATIC CONVEYOR SYSTEM FOR TRANSPORTING POWDERS AND GRAINS OVER SHORT DISTANCES Dense phase pneumatic conveyor, equipped with multi-nozzle venturi ...

ELECTRO-PNEUMATIC CONVEYOR FOR TRANSPORTING POWDERS AND GRAINS OVER LARGE DISTANCES Dense phase pneumatic conveyor, equipped with multi-nozzle venturi pump, certified ...

... turnkey pneumatic conveying systems: knowledge of the entire range of conveying techniques, knowledge of processes and products based on millions of hours of system ...

... Process patented Air Assist® technology is used for dense phase pneumatic conveying systems and is suitable for fragile and abrasive ...

NTE Process Srl

... potentially cohesive powders, with Air Assist® patented technology, suitable for controlled injection of air along the conveying lines. This technology allows the system ...

NTE Process Srl

... allows their easy and rapid replacement. Furthermore, the very low air consumption allows the use of Smartjet® M530 everywhere, simply by connecting to the existing compressed air ...

NTE Process Srl

... from 24 ltrs up to 4.000 ltrs vessels capacity. These conveyors can be supplied both in dense phase with a cleaning cycle after each launch or in extra-dense phase ...

GVF Impianti Srl

... the application needs. Available sizes go from 24 ltrs up to 1500 ltrs vessels capacity and both dense (with cleaning cycle after each launch) and extra-dense (with full pipeline) versions are possible. ...

GVF Impianti Srl

... equipped with wheels for easy movement. - Compact GA type version - Optional feet on wheels for easy movement. - Pneumatic and electrical panels installed on board - Easy installation under filters, presses ...

GVF Impianti Srl

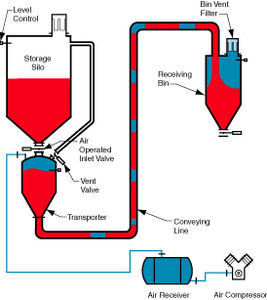

The Dense Phase pneumatic conveying system is used for conveying of dry bulk materials as powders and granules by using a high positive ...

... pressure dense phase gas ash conveying system technologies, namely "upper-drawn fluidized small silo pump system", "downward-drawn booster gas conveying ...

... complete systems for bulk material handling, Coperion & Coperion K-Tron design and manufacture equipment for the pneumatic transport of bulk solids materials for small and large systems. ...

The D Pump is Schenck Process’s unique, self-adaptive Dense Phase Pneumatic Conveying solution. It was developed to overcome the challenges when conveying ...

... product Low wear Low level of dehomogenization High conveying capacity Long transport distances Energy saving due to targeted transport air supply AZO®MULTIAIR dense phase ...

... fragile, sensitive powders or granulated products in pressure dense phase. Capacity Flow rate: from less than 1 tonne/hour up to 20 tonnes/hour. Pressure vessel for dense-phase ...

DENSE PHASE CONVEYING Efficient material transport whilst preserving quality Dense phase pneumatic conveying systems ...

... very low volumes of compressed air at supply pressures of 60-80 psig. Conveying air pressures vary between 25-80 psig, depending upon the conveying characteristics ...

The 2415 venturi loader can be accessed in two different models for basic keep total conveying or loss-in-weight (LIW) feeder refill applications. Additionally it features several dispense valve versions as per the ...

Coperion K-Tron GmbH

The HDP 1000 Brute Force Concept Pressure Conveying System is a dense phase, high pressure, low to medium velocity, batch conveying system. ...

Dynamic Air

... or explosive powder in <1 mJ. It is also supplied with hygienic and sterile units. This product is only the vacuum dens-phase system on the market today due to its unique filtration concept.

Dec Group

... pressure phase pneumatic conveying system, which is an advanced pneumatic conveying system in the world at present. ...

HEFEI TECLION MACHINERY INDUSTRY CO. LTD.

... mandatory transmission is called positive pressure dense phase transmission tank pneumatic transport, general air source pressure is 0.5Mpa ~ 0.7Mpa, operating pressure ...

... valves on silos, CEPATIC system on loading, dispersing valves, magnets, pressure switches and sensors. Slide valves to stop the propagation of explosions and flames in the conveying system. ...

The dense phase conveying technology, using compressed air as the power, through the transmission tank and pipeline, the materials to a certain height ...

... Mastervac in-house technicians recommend using a dense phase pneumatic conveyor for all medium particle size products, such as rice or grains. In fact, the dense phase ...

AIRPULS dense phase pneumatic conveyors, at high and very high concentration, are manufactured in several standard versions to guarantee granules pneumatic conveying ...

PROPULSIVE MACHINE SUITABLE FOR THE PNEUMATIC TRANSPORT (IN SHORT AND MEDIUM ROUTE) OF MATERIAL IN A SOLID PHASE, AND FOR THE MATERIAL TRANSPORT WHERE IT IS NECESSARY TO KEEP SAFE THE PRODUCT ENTIRETY. TECHNICAL ...

PIP-type feed conveyor for pneumatic dense-phase conveying by pushing. Thanks to their high load capacity and low operating speed damage to the transported goods is minimised. ...

HOSOKAWA SOLIDS, S.L.

... DESIGN OF PNEUMATIC TRANSPORT SYSTEMS IN DENE AND IN DILUTED PHASE, EXPLOITING THE PRESSURE OF THE TECHNICAL GASES (AIR OR NITROGEN) PRESENT IN THE CUSTOMER'S NETWORK, OR USING COMPRESSORS ...

... use pressure or vacuum pneumatic conveying systems in their different modalities. Conveying in dense phase Low ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining