- Production Machines >

- Other Manufacturing Equipment >

- Industrial die casting

Industrial die casting

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Casting offers unlimited freedom in design and material choices. Matson is specialized and experienced in supplying high-quality custom castings together with a broad range of secondary operations like ...

Metal fabrication is the process of manufacturing products from raw material using individual processes such as cutting, bending, welding, grinding and assembling. Matson provides custom metal fabrication with capabilities well beyond ...

... metallo-plastic inserts and sub-assemblies meets numerous product requirements, increases technical feasibility and enhances industrial performance. Technical know-how and extensive capacity With a fleet of 100 injection ...

... metallo-plastic inserts and sub-assemblies meets numerous product requirements, increases technical feasibility and enhances industrial performance. Technical know-how and extensive capacity With a fleet of 100 injection ...

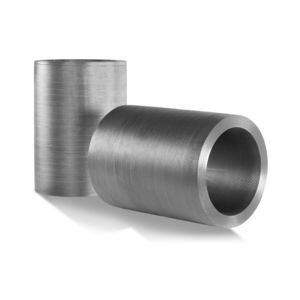

It can die cast complex thin-walled parts. Die castings can have complex part shapes, and the wall thickness of parts can be small.

Gravity-die casting, sawing, sanding and finishing (includes a number of stages depending on the specification of each piece: deburrer, file, polisher …) machining and forming include processes such as ...

... overmoulding Bi- and Tri-injection Co-injection Heat and cool (Roctool) Gas injection Injection compression Chemical foaming Physical foaming injection (Mucell) Zamak injection Extrusion blow-moulding Thermo ...

... chamber die casting machines is very environmentally friendly, and zinc die cast parts are 100 percent recyclable. Zinc die cast products can save material, energy ...

... whole parts or ingot. Sometimes further treatments are necessaries after the die-casting in function of the casting or the metal we use: rough down the excess material casting, ...

... Stainless steel Casting process solutions: High pressure die casting Gravity casting Lost wax casting Sand casting Casting ...

A.G.C. BUSINESS CONSULTING S.A.

HIGH PRESSURE DIE CASTING Die casting is a manufacturing method widely used to produce aluminum and other alloy components by pressing the molten metal into reusable ...

With our know-how, you can increase your productivity, process reliability and quality in the sinter industry. CFRC support rings from Schunk set standards with a long service life and outstanding dimensional stability. In order to ensure ...

We realize die casting parts that vary from 10 grams to 10 kg, managing till 10 different alloys. We reach a great quality of our die casts thanks to vacuum technology. The moulds are ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining