- Production Machines >

- Other Manufacturing Equipment >

- Die casting

Die casting

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

CCMS produces lost wax cast steel and alloy steel and ductile iron and various forged parts, all of which are tested for the chemical composition of the material, tensile, yield and elongation tests. Our products include ...

Ningbo CCMS Industrial Co., Ltd.

CCMS produces lost wax cast steel and alloy steel and ductile iron and various forged parts, all of which are tested for the chemical composition of the material, tensile, yield and elongation tests. Our products include ...

Ningbo CCMS Industrial Co., Ltd.

CCMS produces lost wax cast steel and alloy steel and ductile iron and various forged parts, all of which are tested for the chemical composition of the material, tensile, yield and elongation tests. Our products include ...

Ningbo CCMS Industrial Co., Ltd.

Our Customized Die Casting Parts use advanced die casting technology and high-quality materials to provide high precision, high strength and excellent surface quality. ...

... Co-injection Heat and cool (Roctool) Gas injection Injection compression Chemical foaming Physical foaming injection (Mucell) Zamak injection Extrusion blow-moulding Thermo compression DECORATION TECHNOLOGIES PVD Paint Laser Cubic ...

Groupe PLASTIVALOIRE

... chamber die casting machines is very environmentally friendly, and zinc die cast parts are 100 percent recyclable. Zinc die cast products can save material, energy ...

Adolf Föhl GmbH + Co KG

Casting offers unlimited freedom in design and material choices. Matson is specialized and experienced in supplying high-quality custom castings together with a broad range of secondary operations like ...

Hebei Matson Metal Tech Co., Ltd.

PROCESS Die casting is a manufacturing process using large pressure to force the molten metal from the crucible, to the injection covering. After, hydraulic piston inject the molten metal to preformed ...

... Characteristics of the aluminum used in high pressure die casting - At equal volume, aluminum has 34% by weight of steel - Aluminum is an excellent conductor of temperature, 1.8 times better than ...

... DIN 239 In accordance with the customer requirements we can submit the atest of the used material maximal weight of the casting is 12 kg

Blisk Casting

... Stainless steel Casting process solutions: High pressure die casting Gravity casting Lost wax casting Sand casting Casting ...

A.G.C. BUSINESS CONSULTING S.A.

The LEMAN Industrie group’s high level of expertise in moulding and overmoulding is based on a core competence in materials and a total command of hybrid techniques. Overmoulding of metallo-plastic inserts and sub-assemblies meets numerous ...

LEMAN INDUSTRIE

1. Materials: Aluminum alloys 2. Our largest size of the casting is 1500mm(L) x 900mm(W) x 400mm(H). Trade terms 1. Minimum Order Quantity:Small quantity acceptable 2. Payment Term:T/T. L/C. 3. Packing:Standard ...

NANKAI

... including: magnesium alloy die casting, aluminum alloy die casting, precision magnesium alloy die-casting mold, precision aluminum alloy die-casting ...

Glitter Mold Technology Co., Ltd.

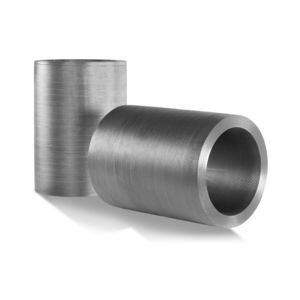

... grade of die castings is it13~it15 in gb/t 1800-2009, and the higher accuracy can reach it10~w 11. The surface roughness is 3.2~1.6um, and locally 0.8um. Because of the high dimensional accuracy and high ...

Qingdao Yonglihao Machinery Co.,Ltd.

... identify the most suitable technology for producing all types of aluminum mechanical components, choosing from: casting , hot pressing , die casting, extrusion or directly from the bar. The ...

... tooling components. Compared with conventional die casting tooling, this manufacturing process can help you save up to 40% in both time and cost from a standard die casting ...

Molding | Injection Molding Casting | Sand Casting, Investment Casting, Die Casting, Gravity Die Casting, Centrifugal ...

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies ...

HIGH PRESSURE DIE CASTING Die casting is a manufacturing method widely used to produce aluminum and other alloy components by pressing the molten metal into reusable ...

During the aluminum casting process, the metal melt is either poured or pressed into the mold. This process is used, for example, to manufacture cylinder heads, wheel rims and many other aluminum castings. ...

... gooseneck casting, is the most ubiquitous die casting process. In this process, the injection mechanism’s chamber is submerged in molten metal and the “gooseneck” metal supply structure ...

Xometry Europe

... RpProto offers high-quality die casting services to our customers. Our high-pressure die casting service can use materials including aluminium, zinc, magnesium, brass, ...

... the die casting process, Xavier took control of the die casting raw material supplier it has cooperated with for more than 5 years in 2018, and increased capital to expand ...

Shenzhen Xavier Precision components Co., LTD.

... Producing our aluminium castings, fully automatic and partialy mechanized molding equipments are used. Single parts and small lot sizes as well as special sizes are produced by hand molding. We produce aluminium ...

With our know-how, you can increase your productivity, process reliability and quality in the sinter industry. CFRC support rings from Schunk set standards with a long service life and outstanding dimensional stability. In order to ensure ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining