- Machine-tools >

- Machining Center >

- Large series machining

Large series machining

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... milling/grinding milling of edges/ends Using our double-head milling machine, we can machine your steel plates with great precision and in record time thanks to our automated machining ...

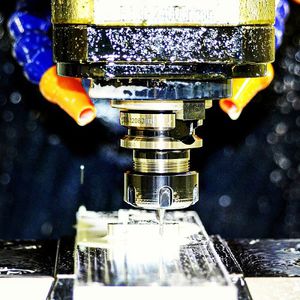

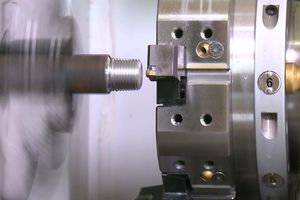

Overview Our CNC machining operation is set up with over 60 CNC machines to cover the full spectrum of machining services including turning, milling, drilling and grinding. Our part envelope is up to ...

Our CNC machining operation is set up with over 60 CNC machines to cover the full spectrum of machining services including turning, milling, drilling and grinding. Our part envelope is up to a 1.5M cube ...

... which is higher quality managerment system. Material: Steel, Brass, Aluminum, Stainless Steel, Plastic Process: CNC Machining, Turning, Milling, Hot Forging, Cold Forging Surface Treatment: Brushing, Anodizing, ...

Phenolic fibers, which under pressure form a stratified plastic material with high mechanical strength and good electrical insulation. It has resistance to chemical agents, high temperatures, and has a low weight. It is widely used ...

... compared to other engineering ceramics. Because it has been a popular ceramic material, we have extensive experience in machining it. Machining to micron accuracy is possible.

Top Seiko Co., Ltd

Aluminum Nitride is stable at very high temperatures in inert atmospheres. Also, it is the only technical ceramic material that offers high thermal conductivity and good electrical insulation. Key Properties ■High thermal stability ■Low ...

Top Seiko Co., Ltd

... toughness. This makes zirconia ideal for a variety of wear resistance applications. It is difficult to manufacture zirconia in large sizes compared to other oxide materials like alumina. In addition, zirconia is a relatively ...

Top Seiko Co., Ltd

Material: Carbon steel: S235JR, S355JR,C45 Stainless steel: SS303, SS304, SS316L Non-ferrous metal: Brass, Alu, Ti alloy Plastic: POM, PP, PE, ABS Process: Turning/Milling/CNC Boring/Drilling/Threading Grinding Size: From ...

Mechanical machining of sheared and drawn parts for the following target industries: Electromechanics Building construction Automotive Motorcycle construction

MACHININGS ON MACHINING CENTRE G.S.I. can internally manage machining on machining center of mechanical transmission systems of 750 mm length and 500 mm width. The machining ...

MACHININGS ON MACHINING CENTRE G.S.I. can internally manage machining on machining center of mechanical transmission systems of 750 mm length and 500 mm width. The machining ...

MACHININGS ON MACHINING CENTRE G.S.I. can internally manage machining on machining center of mechanical transmission systems of 750 mm length and 500 mm width. The machining ...

... supply major customers with small, medium and large parts. The Group machines parts from sheets, castings and metal matrices in compliance with customer specifications. Figeac Aero also provides re-machining ...

Figeac Aero

Milling machines : The company has a large number of the world's cutting-edge metal processing equipment, efficient management team and professional team of technicians, is a purchase of raw materials, ...

MILLING AND PHOTOELECTRIC CELL RESET In order to provide its customers with a product that is more and more complete and of high quality, Fotomeccanica implemented its production department with new machines. We are ...

FOTOMECCANICA SRL

Milling, Turning, Assembly, Unit Parts, Small and Large Series, CFAO: (files - DXF, DWG, IGES, PDF ...)

MECHATECHNIK KFT

UP milled parts are components that due to their geometric shape can only be produced with 4- or 5-axis machines with high-frequency spindle. The MM machines, developed by LT Ultra, make it possible to produce the parts economically and ...

LT Ultra-Precision Technology GmbH

... expertise and know-how in many areas: Production of components and sub-assemblies for gas turbines combustion line, Machining of complex 5-axis parts (impellers, compressor wheels, blades, ...), Production of complex ...

Milling is one of the processes by chip removal machining. The milling process requires a basic equipment. Basic equipment consists of milling machine, work-piece, fixture ...

Our company specializes in complex machining milling for small / medium / large series of parts with dimensions that vary from their machines, “for more details see section ...

Comett

Machining The capacity to perform 150.000 hours of machining annually guarantees flexibility and the ability to satisfy our Customers’ requirements. The machining process includes the ...

... . For the production of parts in series, we propose two types of machining : Conventional digital machining with a succession of turning and milling operations for ...

... general tolerance ≪how to process≫ bar turing machining(5-axis machining equipment) ≪Characteristic≫ If design is weighed heavily instead of functionality, we can support it. 5-axis machining ...

... molded. The best method is molding and machining. DCW Offers: ①Custom Materials & Sizes Our tooling is designed and manufactured in house, enabling us to work with your chosen materials and sizes. ②Small or ...

... cover a large range of products from small to large components in low to high volume production environment. With highly experienced engineers and a quality team who have been working on 3-Axis vertical ...

Adam Fabrication applies Precision Engineering, CNC Machining and Metal Treatment Solutions to many different materials and serves to a wide variety of industries with its machining capabilities. We have ...

... Rotative and cubic machining for production of small, medium and large components in steel, stainless steel, cast iron or nickel-based alloys as well as aluminium alloys. Fulfilment of demanding tolerances. ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining