- Production Machines >

- Plastics Processing >

- Quick mold changer

Quick mold changers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

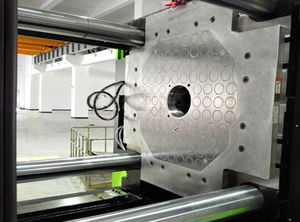

Stäubli quick clamping systems can be used on any machine, new or existing, whether vertical or horizontal loading. Our systems allow you to optimise your production capacity and improve your flexibility and response ...

Stäubli offers unique expertise for the quick change of moulds in the plastics industry. At K 2019, Stäubli will exhibit its innovative interactive injection moulding cell combining all of its solutions for ...

... interface which is constantly optimized according to the needs of customers' front-line operators, it can conveniently carry out quick view of information and set and read alarms detection for various parameters, etc. Diverse ...

The ToolingShuttle 61 combines the crimp applicator (tooling), terminal reel and paper winder into one mobile quick-change unit for CrimpCenter 6-series fully automatic crimping machines. The ToolingShuttle 61 allows ...

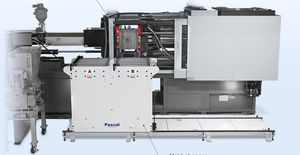

Multiple injection molding machines share a set of automatic mold changing trolley system. This “automatic mold changing trolley system” can effectively solve the mold changing operation ...

Multiple injection molding machines share a set of automatic mold changing trolley system. This “automatic mold changing trolley system” can effectively solve the mold changing operation ...

Discover the innovative Electro Permanent Magnetic Chuck, designed to deliver unmatched precision and efficiency for your machining needs. This advanced chuck technology combines the benefits of permanent magnets and electromagnets, providing ...

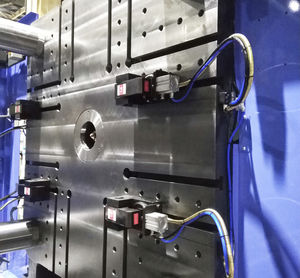

... line of Quick Mold Change products developed to decrease downtime between mold changes. Our solutions include both vertical load and horizontal load style hydraulic clamping systems, ...

The magnetic clamping system employs two types of strong, permanent magnets eliminating the risk of molds falling due to a loss of magnetic force during power outages. Electric power is only used when the magnetic force ...

It is an automatic mold changer which can shorten the mold changing time considerably, comparing with the conventional forklift or overhead crane.

... Smaller Stocks needed. • - Larger Moulds in smaller Machines. • - Uniform clamping => no deformation of the mold when opening => less wear of the mold. • - Better quality moulded Parts. • - No clamps, ...

... permanent type electro-magnetic technology and high safety coefficient, Ferromagnet Fast Mold Fastening Systems connects Sheet Metal Molds, Ceramic Molds, Plastic Injection Molds ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining