- Production Machines >

- Plastics Processing >

- Extrusion line

Extrusion lines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... accumulation, Dekuma has a professional team to research and develop pipe extrusion production line, with more than 40 national patents. It can provide pipe extrusion production line ...

Multi-layer Nylon Automotive Tubes & Bellows Extrusion Line Product characteristics: Lightweight, Excellent Permeability Resistance, Environmental Nylon multi-layer composite pipe can effectively ...

... all kind of bundles, telecommunication fiber cable duct. High Spead Extrusion Line for Silicone core Pipe,12mm silicore core pipe stable reaches 80-100m/min. Extrusion Line ...

PC Endurance Board, Wave Board Scope of application: The Garden, the Amusement Place Strange Decoration and the rest place porch pavilion; the commercial building interior and exterior decoration, the modern city building curtain wall; ...

Jwell Extrusion Machinery Co., Ltd., Shanghai

PP、EVA、EVOH、PS、PE Multi-layer co-extrusion barrier sheet production line Due to the more and more stringent market requirements for products, Shanghai Jinwei developed advanced five-layer symmetric ...

Jwell Extrusion Machinery Co., Ltd., Shanghai

JWELL HDPE PVC TPO Geomembrane Liner Geotextile Fabric Non woven Extrusion Line Making Machine The new technology of JWELL company adopts the composite technology of solid roll to make ...

Jwell Extrusion Machinery Co., Ltd., Shanghai

... the production of physically foamed plastics sheets, pipes, and boards. They meet all of the requirements for an efficient extrusion process. *Output rates of up to 2,800 kg/h in the production of XPS boards *Use of ...

KraussMaffei

... automation components for maximizing material savings. *Increasing cost-effectiveness *Flexible extrusion systems *Procedures for reducing material cost *Extrusion lines for production ...

KraussMaffei

KraussMaffei supplies individual machines and complete profile extrusion systems for all profile extrusion applications. Whether profiles made of PVC, PE or other materials – and irrespective of the profile ...

KraussMaffei

... pipe quality both appearance and inside. Easy and quick changeover between different sizes of moulds. The complete extrusion line runs full-automatically. Corrugator and extruders are synchronously ...

Zhongyun Group

... pipe quality both appearance and inside. Easy and quick changeover between different sizes of moulds. The complete extrusion line runs full-automatically. Corrugator and extruders are synchronously ...

Zhongyun Group

... pipe quality both appearance and inside. Easy and quick changeover between different sizes of moulds. The complete extrusion line runs full-automatically. Corrugator and extruders are synchronously ...

Zhongyun Group

Extrusion lines for PIPES Bausano designs and implements complete lines based on twin-screw extruder technology of the MD Plus family, suitable for production of thermoplastic ...

Bausano & Figli S.p.A.

Extrusion lines for production of pipes Bausano designs and implements complete lines based on extruder technology MD and E-GO series, suitable for production of thermoplastic ...

Bausano & Figli S.p.A.

Extrusion lines for the production of PROFILES The patented MULTIDRIVE technology of the Bausano MD Plus extruder range and a long-standing experience in plastic processing allow Bausano ...

Bausano & Figli S.p.A.

Lohia’s duotec series of tape extrusion lines are a result of progressive R&D coupled with years of experience and represents a distinctive innovation for the Raffia Industry. The process involves ...

Lohia Corp Limited

series of tape extrusion lines are based on the conventional single stage stretching process and have been serving the Raffia Industry for over three decades. The technology has been perfected over time ...

Lohia Corp Limited

Extrusion Coating Lines Lohia’s lamicoat is designed for efficient and precise coating operations on tubular or flat PP/HDPE woven fabric. Both PP & LDPE polymer coating is possible, as is the simultaneous ...

Lohia Corp Limited

Extrusion lines for clear sheet Quality is the starting point for every success. The clear sheet is unrivalled in its ability to illustrate the importance and power of light and transparency. Its ...

Breyer GmbH Maschinenfabrik

Extrusion lines for backlight units (LGP) Your vision is our passion. Maximum optical quality. Essential is what you do not see here. Subtle distinctions do not show at first sight. Brilliant display ...

Breyer GmbH Maschinenfabrik

... remain flexible enough to produce for a series of other applications, which the market demands. The efficiency of the extrusion line is essentially determined by an optimized use of materials. High ...

Breyer GmbH Maschinenfabrik

... corrugated pipe, helically extrusion line Krah production technology is a helical extrusion (spiral wound) Krah pipes, krah machine, krah pipe machine, Krah profiled pipe, ...

double-wall corrugated pipe extrusion lineDWC-2000

$214,000 - $853,000

... corrugated pipe production line Application: to produce variety of drainage and sewerage pipe Features: These production lines equipped with high efficiency single screw extruder ...

At present the composite pipe has been widely used in many applications and various steel-plastic composite pipes have been developed. The Steel Reinforced Polyethylene Spiral Corrugated Pipe (SRPCP pipe) is one of the best solutions ...

Goldstone Orient New Material Technology

Steel Reinforced Corrugated Pipe Machine DN 300 - DN 3000 Stiffness SN 8, SN 12.5, SN 16 Pipe weight reduce 25-50% Material cost reduce 30% Compared with the traditional steel and concrete pipe, the plastic pipe has big ...

Goldstone Orient New Material Technology

Fiberglass tape has the characters of high strength, anti-corrosion and flexible, and the most important thing is that it is an economic material than aramid fiber and carbon fiber. The tape is treated by impregnation process of thermoplastic, ...

Goldstone Orient New Material Technology

... manufacturing, installation, commissioning to training, as well as remote technical support. Flow Chart Description Feeding -> Extruder -> Throttle valve -> Melt pump -> Filter -> Diverter valve -> Under water pelletizer ...

USEON Technology Limited

... range of production lines, allowing you to match your requirements to the exact machine performance. Key Features ·Leading XPS Production Line Manufacturer in China ·Successfully supplied 300 ...

USEON Technology Limited

... does not contribute to the greenhouse effect and pollution atmosphere when it is incinerated. Product Data of Our XLPE Foam Line Product: XLPE foam sheet Output: max. 220kg/h Sheet Width: max. 1800mm Sheet Thickness: ...

USEON Technology Limited

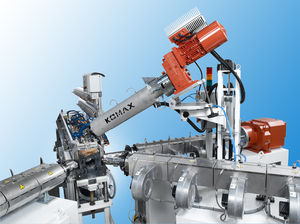

KOMAX offers extrusion lines engineered for tubes and pipes for all customers that need combine very interesting production speeds with high technological content and the highest quality of materials. Double ...

KOMAX SAS

Extrusion line for medical tubes. They are engineered for several different compounds like to PP and POM.

KOMAX SAS

... pool (e.g. tile, board…) Electrical (e.g. ducts for wires…) Available types of KOMAX extrusion lines for profiles KOMAX offers a wide range of extrusion lines ...

KOMAX SAS

For PE pipe production, high output, low power consumption(with real time indicator) , line can be equipped with inner pipe cooling die head* to have excellent wall thickness equality of thick pipe.

Ningbo Extru Machinery Co., Ltd.

For PE-RT I,II pipe production, with high production speed, high precision of tem-perature and unit weight control, low power consumption characteristics. the pipe is widely used for floor heating, hot water transportation etc.

Ningbo Extru Machinery Co., Ltd.

For PPR pipe production, high output, efficient plastication, with surface defect detection*,auto-matic quality sorting* functions etc.

Ningbo Extru Machinery Co., Ltd.

DEFINITION : Without orientation. PROCESS : - Extrusion - cooling - winding APPLICATIONS : Lnon-oriented netting are used for applications requesting a good rigidity, small mesh size (1x1 mm) or for perforated ...

CORELCO

DEFINITION : Mono-orientation, the longitudinal strands are stretched. PROCESS : - Extrusion - cooling - mono orientation - winding APPLICATIONS : mono-oriented netting are used for applications requesting ...

CORELCO

bi-orientation, both strands, longitudinal and lateral are stretched. PROCESS : - extrusion - cooling - mono-orientation - bi-orientation - winding APPLICATIONS : Bi-oriented netting are used for applications ...

CORELCO

Our extrusion lines target the following sectors and are intended for the production of single and multi-layer products: Automobile •Smooth mono-layer and multi-layer tubes for miscellaneous fluids •Single ...

YVROUD

Coating lines YVROUD coating lines were initially intended for cable production, but have found many cladding applications: • Wires and metal cables • Tubes and plastic wires • Optic fibres and ...

YVROUD

YVROUD blown film lines are generally intended for the development of the continuous manufacturing process for the product. They are mainly installed in research centres, inspection laboratories and ...

YVROUD

... cooled blown film line that is well-suited for those seeking a high output co-extrusion line. With Alpha Glacier, customers are able to see and feel the difference with the improvement ...

Alpha Marathon Technologies Group, Inc.

Cast film extrusion lines are recognized in the industry for their high production speed and film quality featuring superb optical characteristics. Alpha Marathon’s cast film lines complement ...

Alpha Marathon Technologies Group, Inc.

... Marathon's Mono and Co-extrusion PVC Film Lines is used for food wrap application and offer excellent properties. Line can produce high quality clear rolls by using PVC compounded material ...

Alpha Marathon Technologies Group, Inc.

EXTOL has five extrusion lines in Spain - 1.8 T, 3 of 2.2. T and 2.8T - and a 2.5 T line at our plant in Nantes (France) with a total capacity of 45,000 metric tons/year. Our company ...

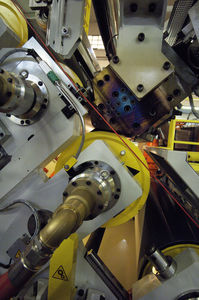

Direct extrusion or inline-compounding facilitates the production of extruded parts in a very economical way by merging various process steps. The stage after the compounding step is shaping. Here the ...

... and manufacturing fully computerized lines for pipe extrusion. PVC pipe extrusion line is one of our specialized items. The Parallel twin screw extruder ...

... wall panels, decorative profiles etc. One line equipment includes Main Extruder, Extrusion Tool, Calibrating System, Calibrating Table, Profile Caterpillar Haul-off, Saw, stacking unit. Extrusion ...

The direct extrusion allows the production of all the “special” filled or reinforced sheets having high technological value with higher performances at considerably reduced production costs. Higher performances obtained ...

ICMA San Giorgio

... twin-screw corotating extruder can show all its quality and advantages. > The extraordinary feeding capacity of a corotating extruder allows the introduction of even 100 % recycled scraps without affecting ...

ICMA San Giorgio

The direct extrusion of sheets made of recycled resins allows the value increasing of a “poor” product. The use of a corotating extruder allows the feeding of recycled scraps with a low selecting level, ...

ICMA San Giorgio

... addition, to complete lines for co-extruded film up to 11 layers, the first water quenched film lines, and blown film lines for products up to 25m in circumference, we offer the widest ...

Davis Standard Extrusion Systems

Tooling for mono- and multilayer extrusion Suitable PVC toolings for a great variety of applications Besides the extruder, pipe heads are one of the most important components in a pipe extrusion line. ...

battenfeld-cincinnati USA

The Customized High-Output Blown Film Line for Demanding Applications YOUR ADVANTAGES Produce a wide product portfolio with one machine Use the largest process window of all machines on the market Produce demanding ...

W&H Group

Within the JUMP reactor, the polymer passes over several slow turning elements which create a polymer film, the surface of which is constantly renewed. The reactor vessel is kept under vacuum, through which ethylene glycol and other volatile ...

Gneuß Kunststofftechnik GmbH

... feeder that quantitatively feeds raw materials into the twin-screw kneading extruder, a cooling water tank that cools the extruded strands, and a pelletizer that cuts the strands. Screw shaft/screw element Various ...

Shibaura Machine

Anti-Contamination The purest nonwoven you have ever produced Enclosure of the spunbond and meltblown system Ceiling above the wire belt Protection for downstream equipment PACKAGE 2 Efficiency More time for really important ...

Reifenhäuser Extrusion Technology GmbH & Co. KG

Your suggestions for improvement:

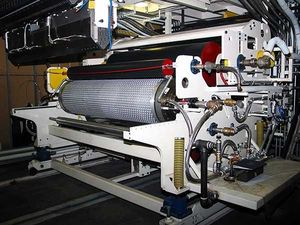

Extrusion lines are used to transform plastics into various products in a continuous manner.

ApplicationsThese installations are designed for the continuous production of plastic film, fibers, profiles and sheets.

TechnologiesThe line consists of several connected components. The plastic is melted in the extruder barrel and pushed through a die, which transforms it into a particular shape. Once it leaves the die, it is cooled and removed at a set rate. The finished product is either rolled for eventual sale by linear measure, or cut into pieces of a specific length.

How to chooseExtrusion lines are built to order. The configuration depends on the raw material to be treated, the finished product to be produced and other characteristics defined by the client.

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining