- Packing - Handling - Logistics >

- Conveying >

- Vacuum pneumatic conveying system

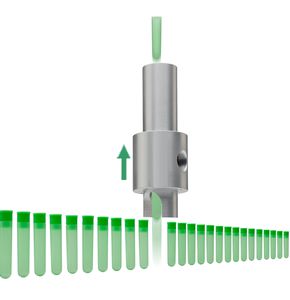

Vacuum pneumatic conveying systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... turnkey pneumatic conveying systems: knowledge of the entire range of conveying techniques, knowledge of processes and products based on millions of hours of system ...

... material loader is equipped with its own control, so that it recognizes when material is needed and automatically starts conveying. This keeps machines running and avoids costly downtime while eliminating material wastage, ...

... conveyor • easy product discharging, full bore opening • purely pneumatic powered systems with failsafe controls • electrical Vacuum Pumps upon request • valves, ...

VOLKMANN

... easily dismantled without tools. PPC Vacuum Conveyors are offered as pre-configured units regarding for the individual application. Customers choose from a variety of Pharma or electrically conductive filter systems ...

VOLKMANN

... of the system. For the conveying of hybrid mixtures, where the transfer of powders containing solvents, the entire vacuum transportation process with an INEX Vacuum ...

VOLKMANN

... to the applications; • Customized piping, joints, vacuum lances for each application; • Double control system: electro-pneumatic and with PLC. Advantages: ...

POWDER DS has two systems of pneumatic conveyors, according to the needs of the installation: conveyors by suction or by pressure. Conveying by suction ...

... suitable for conveying over very long distances (commonly up to 300 metres) Features Easy to connect The Tetra Pak® Pneumatic Conveyor PDP FO is powered by compressed air, and can be easily connected ...

... the innovative vacuum conveying system in which the suction capacity can be split as required. The valve technology on the vacuum manifold allows the ...

... up to 8 vacuum pumps and up to 64 receivers assigned to any combination of pumps • A vacuum manifold connects receivers to the assigned vacuum unit that supplies all ...

... through which the suction unit creates vacuum inside the transport line - pipe line and filter where the materials arrive- capable of generating an air flow that conveys the product In ...

dena aspirazioni industriali

... • Slow and gentle conveying with less compressed air and energy consumption • Simple, cost-effective system assembly • Less wear and tear due to low speed • No segregation ...

HOSOKAWA SOLIDS, S.L.

... movement of materials, pneumatic conveying systems are used. RIBO has specifically studied ad hoc solutions to overcome these difficulties: let’s see how they work. How pneumatic ...

... for pneumatic conveying - Ø of passage : from 4 to 100 mm Features: - In-line venturi with straight duct specialized for pneumatic conveying - Fully static, instant ...

... specifications: - Fluid: compressed air - Optimum pressure: 5.5 bar - Pressure range: 0 to 10 bar - Temperature range: - 50° to + 250°C Further information: Pneumatic conveying ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining