- Packing - Handling - Logistics >

- Conveying >

- Vibrating feeder

Vibrating feeders

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... rate can be individually adjusted; the vibration amplitude is precisely controlled – for absolute uniform feed of even smallest quantities. Safe and reliable. The Vibratory Feeder LABORETTE with a V-shaped ...

... rate can be individually adjusted; the vibration amplitude is precisely controlled – for absolute uniform feed of even smallest quantities. Safe and reliable. The Vibratory Feeder LABORETTE with an ...

... feeds 2 slides/spindles Upon request: basic structure to support the feeder, equipped with aluminum base plate already prepared with the holes that allow to fix the suitable feeder on it. With aluminum ...

Vibrating Rock Feeders, which feed the raw mines and materials to the crushers, are produced to serve for years in the harsh conditions of the mine sites. They are suitable for material loading with ...

... ground. The feeder bunker truck is filled with a bucket or conveyor belt system and the material can be regularly fed directly to the belt conveyor, screen, or trucks thanks to the vibrating system. General ...

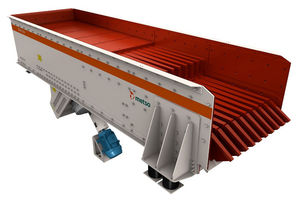

Metso VF Series grizzly Feeders are primary feeders suitable for all primary feeding applications. Your primary feeder partner Features Metso VF Series grizzly feeders ...

“High Deflection” Vibratory Feeders combine the higher deflection 3/16- inch (4.8 mm) and lower frequency (30 cps) advantages of a mechanical feeder with the trouble–free service of an electromagnetic ...

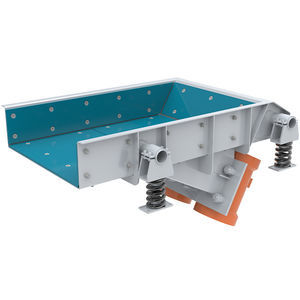

Eriez HVF mechanical feeders are straight-forward, rugged, vibrating machines that move high volumes of bulk materials reliably and economically. The feeder is a two-mass vibrating ...

Our heavy duty line of Brute Force feeders provide a cost effective means to feed or screen large volumes of bulk material for applications where limited feed rate adjustability is required. Brute Force feeders ...

... with dampers on supports. • Possibility of inspection gate with quick closing mechanism at the discharge end of the vibrating feeder.

Batch feeder for homogeneous powder, dense or dry products. Particularly suitable for use in the food, chemical, and pharmaceutical industries. • Truncated conical load hopper capacity of about 30 litres of stainless ...

... works in the direction of the resultant force. Simple harmonic vibration. The feeding process of the feeder is realized by the reciprocating linear vibration of the feeding trough along the inclined direction. Application ...

... pollution. The vibrating feeder is composed of a feeding trough, a vibration exciter, a spring support, and a transmission device. The vibration source of the vibrating ...

... VOLKMANN vibrating feeder can be used in a variety of ways and, in combination with a vacuum conveying system and a level indicator control, is ideal for the automation of feeding processes. Depending ...

... spindle, thanks to the abrasion-resistant surfaces of the feeder. A noise-insulated vibration mechanism ensures propulsion, and noise emissions can be further reduced with an optional sound enclosure ...

The CentriFeeder line of feeders provides accurate, real-time flow measurement, as well as near perfect control of flow rate and total. For blending applications, control the flow rate of an individual ingredient, or ...

SCREW FEEDERS - from bench with vibrating screws positioning

... production lines and assembly systems. Advantage Vibrating feeder consume very small electric power by means of utilizing the resonance phenomenon, which is extremely economical. Vibrating ...

ERGA vibrating feeders are used for bulk and lumpy material discharge from hoppers or uniform and dosed feeding to components of processing plants and lines. - Wide range of designs and applications: ERGA ...

GVF Impianti vibrating feeders are constituted by a vibrating canal, which can be coated by wear-resistant materials, activated by two adjustable eccentric en-masse electro-vibrators. The ...

The Pharmalift is the ideal bulk feeder for integration with either tablet counting machines or blister machines. Pharmalift Features Include: • Large product hopper at low level • Limited contact parts for quick ...

... of the crushing plant to receive the raw material. They are usually followed by a vibrating feeder to continuously feed the material to the crusher. Vibrating feeders ...

Boratas Machinery

... plant. They are usually followed by a vibrating feeder and in some cases by a grizzly screen. The hoppers are very important because they ensure the loading of ail the materials to be crushed. The ...

Boratas Machinery

... beginning of the crushing plant. They are usually followed by a vibrating feeder. The hoppers are very important because they ensure the loading of ail the materials to be crushed. The vibrating ...

Boratas Machinery

Dressing reminding alarm: when dressing number is reached, it will stop the hopper and remind operator to dress. When no workpiece grinding, the machine will count time. If it taking too much time, the hopper will stop. After the operator ...

The Electromagnetic Feeder, manufactured by Tarnos, is specifically designed for feeding a broad variety of bulk material, from storage hoppers or silos to belt conveyors, mills, dryers, mixers applications. It has a ...

TARNOS

The RF series manufactured by Tarnos, is an electromechanical vibratory feeder that runs on a 90 - 650 t/h. It features a low power electric motor that is capable of a stable operation. This device also provides a smooth ...

TARNOS

... power electric motor, high vibration stroke for difficult product, single motor-exciter, rapid and smooth starting and stopping, regulation and reduced maintenance. We have years of experience designing this kind ...

TARNOS

The cost-effective Direct Drive Feeder™ (and conveyor) meets all the process requirements of bulk handling industries and can be configured horizontally or inclined to fit your exact floor space. Drive mechanism The ...

... vibratory feeders provide excellent gravimetric feeding of very free flowing bulk materials. The Coperion K-Tron K3 line of vibratory feeders features improved high accuracy thanks to innovative patent-pending ...

... surface quality. Perfect powder conditioning The fluidized work container, the optional AZO rotary sieve and the optional vibrating table support optimum powder preparation. Clear and user-friendly operating interface The ...

Vibratory feeder for free flowing bulk solids The economical problem-solver with very special characteristics. The Feeder is fitted with a maintenance-free vibratory (VB) trough. This provides optimal ...

... efficiency and lower operational cost. High performance VF Series™ grizzly feeders use a strong linear vibrating motion to effectively move material forward. The feeders have ...

Metso Corporation

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining