- Machine-tools >

- Finishing Machine >

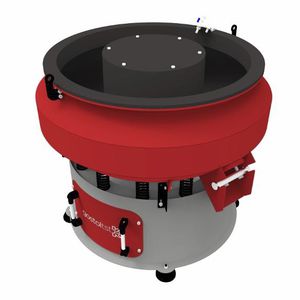

- Vibratory finishing machine

Vibratory finishing machines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Power: 0.1 kW - 4 kW

The tub slide grinding machines have a capacity from 18 to 240 l. They make it possible to process workpieces with different shapes and sizes. Sensitive workpieces can be contactless processed by means of chambers or ...

Power: 0.37 kW - 11 kW

Rotational speed: 1,200 rpm - 1,500 rpm

... drier or centrifuge, the rotary vibrator is upgraded to a fully automatic vibratory grinding centre. Features - Simple emptying via an outlet at the side of the machine - With timer - Sturdy, ...

Power: 0.7 kW

Rotational speed: 2,700 rpm

The washing machine-sized tub vibratory finishing machine with a capacity of 95l is our standard machine and ideally suited for prototypes and small ...

Power: 1.3 kW

... options for mass finishing, deburring, edge rounding and polishing. This tub vibrator is suitable for applications such as the finishing of bone nails and bone plates. Thanks to its unique design, this ...

Power: min 3.7 kW

Rotational speed: min 1450.0 rpm

Vibration grinding machine with muffler cover 1. High output, high effificiency, energy saving, long life, low noise, no pollution, high quality. 2. It is suitable for the fifinishing and fifinishing of large quantities ...

Power: min 3.7 kW

Rotational speed: min 1450.0 rpm

Vibration grinding automatic polishing machine (with discharge device) The vibrating grinding and decorating machine is a working principle that the vibrating motor is used as an excitation source ...

Power: min 3.7 kW

Rotational speed: min 1450.0 rpm

... abrasive move in the working groove of the machine, so that the workpiece and the abrasive run in one direction and rub each other to achieve the effect of surface treatment. 2. It is suitable for the finishing ...

Power: 0.17 kW - 11 kW

Rotational speed: 1,200 rpm - 1,500 rpm

KVM Series - Circular Vibratory Finishing Machines The KVM Series Circular Vibratory Finishing Machines are ideal for deburring, polishing, ...

Power: 0.1 kW - 4 kW

Rotational speed: 0 rpm - 1,500 rpm

TVM Series - Trough Type Vibratory Finishing Machines The TVM Series Linear Vibratory Finishing Machines are designed for efficient ...

Power: 3 kW

Rotational speed: 0 rpm - 3,000 rpm

FPM 150 Wheel Rim Cleaning and Polishing Machines The FPM 150 is a highly efficient machine designed specifically for cleaning, polishing, and removing surface roughness on wheel rims, widely used ...

Power: 0.6 kW - 11 kW

Rotational speed: 1,500, 1,800 rpm

CCL vibratory finishing machine - Perfect choice for system layout ✓Features CCL series provides the multi-purpose finishing suitable for variable size workpieces. ...

Tipton Corp.

Power: 1.5 kW - 11 kW

Rotational speed: 0 rpm - 1,800 rpm

Efficient mass finishing for the toughest requirements With a circular vibrator from our CB range, you get a mass finishing machine that works efficiently and achieves perfect processing ...

Walther Trowal GmbH&Co.KG

Power: 180 ch - 960 ch

This rectangular vibrator mod has a thermo-acoustic cover with tank steened of antiabrasive polyurethane for gold, silver and fancy jewelry.

LM srl

... America and all of our vibratory finishing machines will provide you with the best surface enhancement for your parts. Giant Finishing can help you choose the right vibratory ...

GIANT FINISHING

Power: 0.37 kW - 11 kW

Rotational speed: 1,500 rpm

DESCRIPTION Vibratory bowl finishing machine is among the most commonly used types of machines for vibratory finishing because it has ...

Gostol TST

Vibratory Bowl Mass Finishing Systems Vibratory Bowl Finishers operate by placing a mixture of your parts together with polishing media in a bowl-shaped machine that ...

Power: 0.14 kW

compact dimensions and weightrefreshing of tarnished jewellery from your shopsafe and gentle treatment of fine workpieces, no impingement on the workpiecessimultaneous Processing of workpieces with différent weight, size and geometryprocess ...

AVALON

Power: 7.5, 1.5, 4 kW

Rotational speed: 0 rpm - 180 rpm

PERS offer 4 kinds of Turbo deburring machines. The range offer machines from manual to fully automized machines

PERS

Power: 2.25 kW - 15 kW

NEW INNOVATED ROTAR PATENTED BI-ARC SHAPE 3-D VIBRATORY FINISHING MACHINE VBJ series Plus 35% processing efficiency Features: •New Innovated Bi-Arc shaped working barrel incorporated ...

ROTAR

These machines are especially designed for the finishing of long and large sized components that can not be easily processed in round shaped vibratory machines. In tub ...

KROMAS

Satellite centrifuges are rotating machines and not vibrating. They are among the most efficient equipment for most of the operations of polishing and deburring. These facilities consist of the following families : Satellite ...

Abc Swisstech

Power: 2.16, 3.44, 0.9 kW

... Vortex machines feature an integral drive. This drive offers lower maintenance, higher frequency and a faster process time. Medium frequency machines (1,800 RPM) Proven Weldment Design Faster Material ...

Hammond Roto-Finish

The workpieces to be processed are put into the work container (vibrating bowl), together with the grinding media, water and chemical compound. The vibration of the bowl creates a relative motion between the workpieces and the grinding ...

Perfect Finish GmbH

Kalamazoo Industries Inc. KVF3 vibratory finisher is built with a 1HP 1PH 110V motor with timer switch. Great for deburring, polishing, de-rusting, finishing! 3.3 cubic ft. U shaped tub rotates media ...

The Wheelabrator Vibro Rotary Disc machines offer an alternative to traditional vibratory equipment by using powerful centrifugal forces to process components. The machines can be used ...

Vixen's Vibratory Bowls are easy to operate with standalone controls These machines are also equipped with an internal pneumatic separation device; this ensures efficient separation of the media and ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining