- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

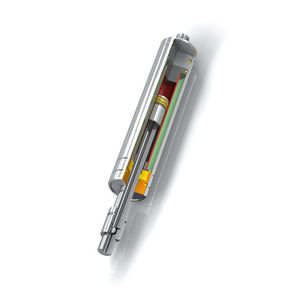

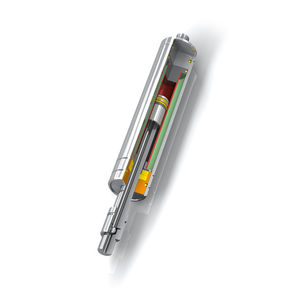

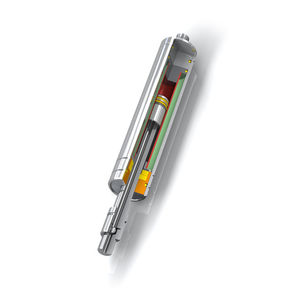

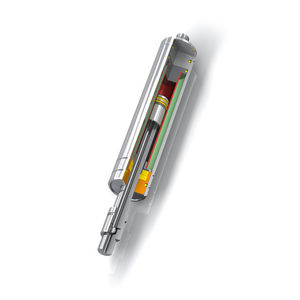

Industrial use gas spring GZ-40traction

Add to favorites

Compare this product

Characteristics

- Applications

- for industrial use

- Other characteristics

- traction

- Force

Max.: 5,000 N

Min.: 500 N

Description

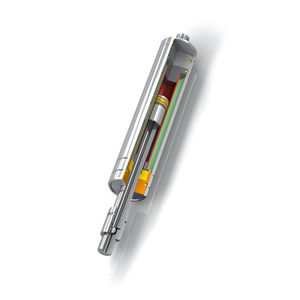

Industrial Gas Springs – Pull Type

GZ-40

Very low progression rate

Valve Technology

Stroke 100 mm to 600 mm

The solution to a lack of space: If standard push type gas springs cannot be used due to a lack of space, ACES' industrial pull type gas springs come into their own. They work in the opposite way to standard push type gas springs. The piston rod is retracted when the cylinder is unloaded. The gas pressure in the cylinder draws the piston rod in.

ACE pull type gas springs offer the maximum service life thanks to the solid chrome-plated piston rod and an integrated sliding bearing. The maintenance-free and ready-to-install products are available in body diameters of 15 mm to 40 mm as well as forces from 40 N to 5,000 N and are available from stock with valve and large selection of accessories. The traction force can be subsequently adjusted using the valve.

Gas traction springs from ACE are used in industrial applications, especially in mechanical engineering and in medical technology as well as in the electronics and furniture industries.

Stroke 100 mm to 600 mm

Piston rod diameter Ø 28 mm

Progression Approx. 43 % to 45 %

Lifetime Approx. 2,000 m

Operating temperature range -20 °C to +80 °C

Material Outer body, End fittings: zinc plated steel; Piston rod: steel with wear-resistant coating

Operating fluid nitrogen gas

Mounting with piston rod upwards

End position damping length Without damping. For end position damping use damping material (e.g. TUBUS or SLAB).

Positive stop External positive stop at the end of stroke provided by the customer.

Catalogs

Main Catalog 2018

294 Pages

Other ACE Stoßdämpfer GmbH products

Industrial Gas Springs - Pull Type

Related Searches

- ACE anti-vibration mount

- Machine foot

- ACE shock damper

- ACE hydraulic damper

- ACE metal anti-vibration mount

- Metal foot

- Leveling foot

- ACE mechanical damper

- ACE metal damper

- ACE industrial damper

- ACE rubber anti-vibration mount

- Elastomer foot

- ACE machine damper

- ACE plastic damper

- ACE cylindrical anti-vibration mount

- ACE vibration damper

- ACE adjustable damper

- ACE gas spring

- Rubber anti-vibration mount

- ACE steel damper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.