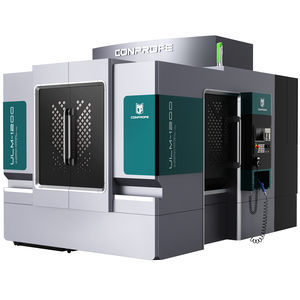

Ultrasonic CNC machining center ULM-500B3-axisverticalwith rotary table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- with rotary table

- Machined material

- for aluminum, for composites, for glass, for ceramics, quartz

- Spindle mount

- HSK-E40

- Number of tool stations

- 12 tools

- Applications

- for panels, drilling, cutting, for drilling, for matrices, for the aluminum industry, for the automobile industry, for automatic tool changers, heavy-duty, for the plastics industry, dental, for bar machining, for the steel industry, for small parts production, for cast iron, for aluminum profiles, for the aeronautical industry, for small workpieces, for sheet machining, for aeronautics, for vehicles, for molds, for heavy-duty machining, for large workpieces, for the mold industry, for medical applications, for titanium, optical, for profiles, for windows and doors, for window and door frames

- Other characteristics

- all-in-one, milling, high-speed, high-performance, laser, multi-spindle, with waterjet cutting, with pallet changer, single-head, for micro-machining, with control panel, ultrasonic, high-productivity, compact, medium-sized, for production, direct-drive, with pneumatic clamping, high-power, tapping, two-station, hydraulic, with gantry loader, rigid, automated loading/unloading, hydrostatic, contour, wide, conveyor belt, honing, with turret, slot, high-speed, engraving, EDM, CE, with linear motor, precision, modular, variable-speed, wet, mobile, tilting-head, chamfering

- X travel

500 mm

(20 in)- Y travel

400 mm

(16 in)- Z travel

300 mm

(12 in)- Rotational speed

40,000 rpm

(251,327 rad.min-1)- Power

10.5 kVA

(14.28 hp)- Work feed X-axis

10 m/min

- Work feed Y-axis

10 mm/min

(0 in/s)- Work feed Z-axis

10 mm/s

- Table load capacity

200 kg

(441 lb)- Tool weight (max)

3 kg

(6.6 lb)- Positioning accuracy

0.005 mm

(0 in)- Repeatability

0.003 mm

(0 in)- Weight

3,500 kg

(7,716.18 lb)- Overall length

1,650 mm

(65 in)- Overall width

1,880 mm

(74 in)- Overall height

2,405 mm

(94.7 in)

Description

The new design of ULM-500B, integrated with Comprofe ultrasonic technology, effectively reduce cutting force and temperature, longer tool life, meet the needs of high efficiency and precision machining of hard-brittle materials and composite materials, suitable for 3C, medical, semiconductor and other industries.

·Powerful Ultrasonic Functions

-With a unique spindle and ultrasonic emission unit integration design, ultrasonic transmission is more stable and ultrasonic machining is more reliable. Spindle speed up to 30,000rpm.

-Highly rigid HSK-E40 ultrasonic tool holder with higher dynamic balance performance for ultrasonic milling, grinding and drilling, significantly reducing cutting forces and achieving higher machining efficiency and surface quality.

-Intelligent ultrasonic system with frequency tracking function for constant amplitude control.

·High Rigidity Design

-one-piece beam column design and gantry structure to ensure the machine has higher rigidity and thermal stability, to meet the needs of high precision and high surface quality machining.

Features

Conprofe independently-developed Ultrasonic Machining System to solve issues in machining hard-to-cut materials

Optional Supercritical CO₂ or MQL Cooling System to realize clean machining

Two options for screw guides to meet requirements on machining hard-brittle materials and metal

Front-door loading & unloading and side-door operation available with facilitative operating position

High-precision machining with up to 3μm of positioning accuracy and 2μm of repeatability

Single/double/T40 chain-type tool magazine available

With chip auger for smooth and thorough chip removal

VIDEO

Catalogs

ULM-500B

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

The 6th Global Semiconductor Industry (Chongqing) Expo

7-09 May 2024 Chongqing (China)

More information

The 24th Lijia International Intelligent Equipment Fair(CWMTE )

13-16 May 2024 Chongqing (China)

More information

Related Searches

- Conprofe machining center

- Conprofe vertical machining center

- Conprofe 3-axis machining center

- Conprofe precision machining center

- CNC milling machine

- Conprofe 5-axis machining center

- Vertical CNC milling machine

- Conprofe high-precision machining center

- 3-axis CNC milling machine

- Conprofe rigid machining center

- Conprofe high-performance machining center

- Conprofe gantry machining center

- Conprofe high-rigidity machining center

- Conprofe milling machining center

- Conprofe cutting machining center

- Conprofe column type machining center

- Conprofe high-productivity machining center

- Applications CNC milling machine

- Conprofe aluminum machining center

- BT 40 CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.