- Products

- Catalogs

- News & Trends

- Exhibitions

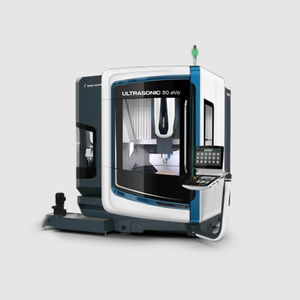

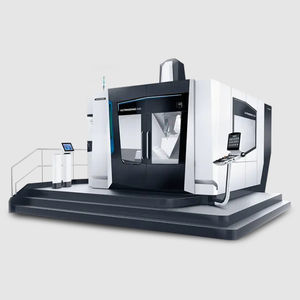

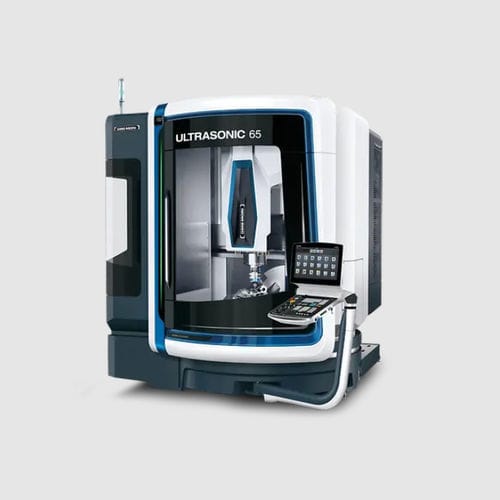

3-axis machining machine 65universalwith rotary tableHSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- universal

- Structure

- with rotary table

- Spindle mount

- HSK A-63

- Other characteristics

- ultrasonic

- X travel

735 mm

(29 in)- Y travel

650 mm

(26 in)- Z travel

560 mm

(22 in)- Rotational speed

30,000 rpm

(188,496 rad.min-1)- Workpiece max height

500 mm

(20 in)- Table load capacity

1,000 kg

(2,205 lb)

Description

ULTRASONIC technology integration - reduced process forces for higher productivity

Technology integration via HSK-A63 interface for ultrasonic superimposition of the tool rotation with amplitudes up to 15 µm

Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra <0.1 µm, longer tool life

Specific coolant treatment systems with centrifuges, optimized for the ULTRASONIC processing of Advanced Materials

ULTRASONIC 3rd Generation - Optimal process control through intelligent controls

Constant amplitude in the process to ensure reproducibility

Automatic detection of the working frequency, significantly improved hardware for signal acquisition

Frequency tracking and simultaneous power control in real time for optimal process stability

Ensuring the ULTRASONIC advantages even with non-optimal tools

Fully compatible with 2nd generation ULTRASONIC actuator

Ergonomic

Large door opening of 1,500 and unique access to the working area, most compact machine with a footprint of just 12 m²

Unrestricted crane loading of up to 1,500 kg

Quick and easy to set up thanks to it´s three-point support

Precise

Comprehensive cooling measures, high-performance coolant unit and multi-sensor compensation as standard

From 5 µm positioning accuracy in standard

Stiff construction with high static masses and balanced moving parts

Versatile

Several table solutions from the 5 axes machining with up to 1,500 kg or complete machining with milling and turning with up to 2,050 Nm

Widest spindle range on the market with up to 30,000 rpm or with up to 430 Nm

Machine integrated tool magazines with up to 180 pockets

Related Searches

- DMG MORI machining center

- DMG MORI vertical machining center

- DMG MORI lathe

- DMG MORI 3-axis machining center

- DMG MORI CNC lathe

- DMG MORI precision machining center

- DMG MORI 2-axis lathe

- DMG MORI CNC milling machine

- DMG MORI 5-axis machining center

- DMG MORI vertical CNC milling machine

- DMG MORI high-precision machining center

- DMG MORI 3-axis CNC milling machine

- DMG MORI rigid machining center

- DMG MORI high-precision lathe

- DMG MORI gantry machining center

- DMG MORI high-rigidity machining center

- Drilling machine

- Milling CNC machining center

- DMG MORI cutting machining center

- Column type CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.