- Metrology - Laboratory

- Metrology and Test Equipment

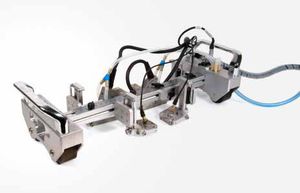

- 1D scanner

- Evident - Olympus Scientific Solutions

1-axis scanner HSMT-Flexinspectionfor welding inspectionfor NDT

Add to favorites

Compare this product

Characteristics

- Number of axes

- 1-axis

- Applications

- inspection, for welding inspection, for NDT, for pipes

- Technology

- ultrasonic

- Other characteristics

- manual

- Length

263 mm

(10 in)- Width

466 mm

(18 in)

Description

The HSMT-Flex™ is intended for one axis encoded inspection of circumference welds on pipes of 4.5 in. OD (114.3 mm) and greater. The scanner comes equipped with four probe holders but can be mounted with a total of eight probes with optional probe holders. Mounted probes can be either phased array or conventional UT for most efficient inspections.

The major characteristic of the scanner is its capacity to bend in the center. This allows the scanner to fit on smaller pipes and also to bring the force of the spring-loaded arm in the radial direction of the pipes for better stability of the wedge, and therefore, optimum data acquisition. For the same reason, optional probe holders that are installed on the outside of the scanner can also pivot.

The HSMT-Flex also allows one of its side frames to slide. This feature allows having the probes mounted on the outside of the scanner. This provides a configuration that is well-suited for hard-to-reach places such as pipe-to-component welds.

Standard Inclusions

• Scanner frame with handles, and:

• Two 340 mm (13.5 in.) frame bars

• Two 500 mm (20 in.) frame bars

• OmniScan-compatible waterproof spring-loaded wheel encoder with 5 m cable

• Four 90º probe holder brackets

• 4 spring-loaded arms (SLA)

• 4 TOFD-P/E 31.75 mm yokes

• 2 PA 40 mm × 55 mm yokes

• Irrigation tubing and accessories

Options

• Umbilical

• Remote Pulser/Preamplifier

• Couplant-Feed Units

• Laser Guide Kit

• Battery-operated laser-guiding device for easier weld tracking.

• Yokes

• TomoScan FOCUS LT Encoder Cable Adaptor

• Replacement encoder

• Probe holder Kits

• Set of two spring-loaded arms (SLA) mounted on 90º brackets, to allow more than four probes.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other Evident - Olympus Scientific Solutions products

Weld Inspection Scanners

Related Searches

- Portable testing system

- Thickness measuring machine

- Digital tester

- Coating thickness gauge

- Digital display thickness gauge

- Evident Olympus inspection scanner

- Evident Olympus flaw detector

- Handheld thickness gauge

- High-resolution scanning system

- Ultrasonic thickness measuring machine

- Compact scanning system

- Portable scanning system

- Evident Olympus mobile flaw detector

- Evident Olympus 2D scanner

- Automatic calibration thickness gauge

- Handheld tester

- Stationary thickness measuring machine

- Metal thickness gauge

- Evident Olympus portable flaw detector

- Magnetic thickness gauge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.