- Machine-tools

- Machining Center

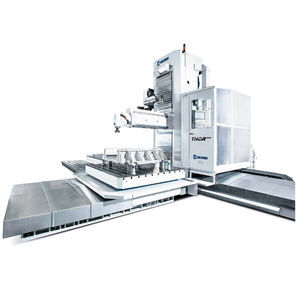

- 5-axis CNC milling machine

- FFG Europe & Americas

5-axis CNC milling machine SACHMAN T/TRT3146-axisuniversaltraveling-column

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis, 6-axis

- Spindle orientation

- universal

- Structure

- with rotary table, traveling-column

- Spindle mount

- ISO 50, HSK-A 100

- Number of tool stations

- 24 tools, 40 tools, 60 tools, 120 tools, 48 tools, 80 tools

- Other characteristics

- high-precision, high-performance

- X travel

2,500 mm, 3,000 mm, 3,500 mm, 4,000 mm

(98 in, 118 in, 138 in, 157 in)- Y travel

1,600 mm

(63 in)- Z travel

1,500 mm, 2,000 mm

(59 in, 79 in)- Rotational speed

4,000 rpm, 5,000 rpm, 6,000 rpm

(25,133 rad.min-1, 31,416 rad.min-1, 37,699 rad.min-1)- Power

35 kW, 47 kW

(47.59 hp, 63.9 hp)- Work feed X-axis

24,000 mm/min

(16 in/s)- Work feed Y-axis

24,000 mm/min

(16 in/s)- Work feed Z-axis

24,000 mm/min

(16 in/s)- Table load capacity

12 t

(13 us ton)

Description

Sachman T314 and TRT314 are large machining centers with 3+2, 4+2, 5 and 6 axes and a traveling column moving along the transverse axis. The T314 milling center offers a traveling table moving along the longitudinal axis, the TRT314 machining center a traveling NC rotary table moving along the X-axis.The large milling head selection means these milling machines are versatile for use in precision engineering, for 3D machining on 3 or 5 axes in mold making and in the aviation industry.

ADVANTAGES

HOW TO BENEFFIT FROM SACHMAN T/TRT314 MACHINING CENTERS

Sachman T/TRT314 machining centers ensure a large chip removal volume due to their large-scale structure and high dynamic. So even 3D machining can be realized. The design of these machines ensures removal volumes and geometry regardless of the carrier's lateral position.

MAXIMUM STABILITY

Sachman T/TRT314 milling centers are equipped with a generously dimensioned cast structure for better damping of machining vibrations. The column itself was constructed in a pyramid shape, the upper part is narrower and lighter than the lower part. Shifting the center of gravity to the lower section enables high dynamic and rigidity.

The linear axes on Sachman T/TRT314 milling centers consist of 65, 65 and 55 mm roller guides for the X-, Y- and Z-axis. The rotary table is moved by a preloaded double rack and pinion drive with automatic backlash compensation. The linear and rotation axes are equipped with direct glass scales for continuously high precision.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- High-performance CNC machining center

- High-precision turning center

- Applications CNC milling machine

- Aluminum CNC machining center

- Turning center with turret

- 12 tools turning center

- BT 40 CNC machining center

- Spindle lathe

- Bridge CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.