- Products

- 3-axis machining center

- FFG Europe & Americas

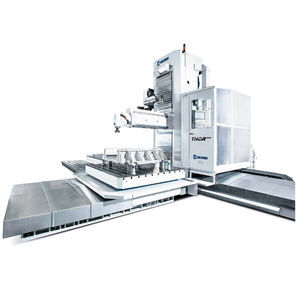

3-axis CNC milling center SACHMAN FRAZERhorizontaltraveling-columnHSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- horizontal

- Structure

- traveling-column

- Spindle mount

- HSK A-63, HSK-A 100, ISO 50

- Applications

- for sheet metal

- Other characteristics

- high-performance, high-rigidity

- X travel

3,000 mm, 4,000 mm, 5,000 mm, 6,000 mm, 7,000 mm

(118 in, 157 in, 197 in, 236 in, 276 in)- Y travel

1,500 mm, 2,000 mm

(59 in, 79 in)- Z travel

1,100 mm

(43 in)- Rotational speed

5,000 rpm, 8,000 rpm, 12,000 rpm, 18,000 rpm, 20,000 rpm

(31,416 rad.min-1, 50,265 rad.min-1, 75,398 rad.min-1, 113,097 rad.min-1, 125,664 rad.min-1)- Power

Min.: 25 kW

(33.99 hp)Max.: 48 kW

(65.26 hp)- Work feed X-axis

35,000 mm/min

(23 in/s)- Work feed Y-axis

35,000 mm/min

(23 in/s)- Work feed Z-axis

35,000 mm/min

(23 in/s)- Table load capacity

2,500 kg, 3,000 kg

(5,512 lb, 6,614 lb)- Tool weight (max)

8 kg, 15 kg, 20 kg

(17.6 lb, 33.1 lb, 44.1 lb)- Tool-changing time

12 s, 20 s

Description

The Sachman Frazer is a medium-sized horizontal machining center with a traveling column moving along the X-axis. This milling machine is available in two versions: as a "box" version with full cladding (roof) and X-axis travels of 3 to 5 m and as an "open" version with exterior cladding and travel up to 30 m along the X-axis.

ADVANTAGES

HOW TO BENEFIT FROM SACHMAN FRAZER UNIVERSAL MILLING CENTERS

Sachman Frazer universal milling machines offer a monolithic column with a thermo-symmetrical structure and movement along the X-axis. The X- and Y-axis slide on large-sized guides with roller shoes. Movement along the Y-axis using three guides ensures maximum rigidity and precision.

MAXIMUM EFFICIENCY

Sachman Frazer milling centers are convincing thanks to their high performance at competitive prices and massively reduced hourly cost. Easy loading and unloading of parts increases their yield rate.

FLEXIBLE USE

Two milling machines versions for the classic supplier market ("box" for general mechanical machining and mold making) and as a customer-specific solution ("open") for aerospace companies and machinery/ general engineering.

IDEAL ERGONOMICS

Sachman Frazer universal milling centers offer a fully enclosed working area with a protection cabin in the machine bed. This ensures optimum coolant and chip removal.

Sachman Frazer universal milling centers can be equipped with continuous or indexed milling heads as well as with heads with electric spindles. Benefit from top precision and surface quality at maximum machining speed for all milling solutions.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.