- Machine-tools

- Machining Center

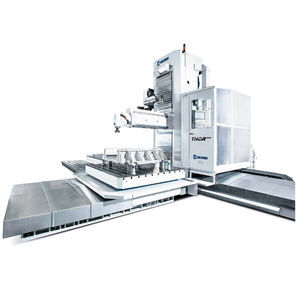

- 5-axis CNC milling machine

- FFG Europe & Americas

5-axis CNC milling machine SACHMAN TS10universaltraveling-columnISO 50

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- universal

- Structure

- traveling-column

- Spindle mount

- ISO 50, HSK-A 100

- Number of tool stations

- 24 tools, 40 tools, 48 tools

- Applications

- for automatic tool changers

- Other characteristics

- high-precision

- X travel

2,500 mm

(98 in)- Y travel

1,210 mm

(48 in)- Z travel

1,200 mm

(47 in)- Rotational speed

4,000 rpm, 5,000 rpm, 6,000 rpm

(25,133 rad.min-1, 31,416 rad.min-1, 37,699 rad.min-1)- Power

35 kW, 47 kW

(47.59 hp, 63.9 hp)- Work feed X-axis

25,000 mm/min

(16 in/s)- Work feed Y-axis

25,000 mm/min

(16 in/s)- Work feed Z-axis

25,000 mm/min

(16 in/s)- Table load capacity

3 t, 4 t

(3 us ton, 4 us ton)

Description

The Sachman TS10 is a 3+2-axis machining center with a column that moves along the transverse axis. Large cast iron structures mean this milling center combines the chipping capacity of milling machines with the dynamic performance of finishing machines. Sachman TS10 milling centers can be used in mold making and precision engineering.

ADVANTAGES

HOW TO BENEFFIT FROM SACHMAN TS10 MACHINING CENTERS

The technology on Sachman TS10 machining centers, with lateral column movement and omission of a cross carriage, guarantees top geometric precision and chipping capacity irrespective of the transverse axis position. They also provide excellent visibility and spindle accessibility for machining.

MAXIMUM STABILITY

All linear axes are equipped with directly readable glass scales, slide on recirculating ball bearing guides and are driven by a rotary ball screw. The large-scale clamping table on the Sachman TS10 machining center is always supported by the X-bed.

Sachman TS10 milling centers use moveable chain magazines with 24, 40 or 48 (option) positions. Tool changing occurs using the retracted column to prevent interference with the usable working area.

IDEAL ERGONOMICS

Two screw conveyors on the Sachman TS10 milling center feed chips along the X-axis and parallel to the table onto a conveyor belt where the tank and pump for the tool cooling lubricant are located.

Sachman TS10 machining centers are equipped with the KOSMO 3 5000 milling head, which uses ISO-50 tools. It is lubricated with oil that is kept at a constant temperature by a special central cooling system. The head is tensioned by means of Hirth serrations.

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- High-performance CNC machining center

- High-precision turning center

- Applications CNC milling machine

- Aluminum CNC machining center

- Turning center with turret

- 12 tools turning center

- BT 40 CNC machining center

- Spindle lathe

- Bridge CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.