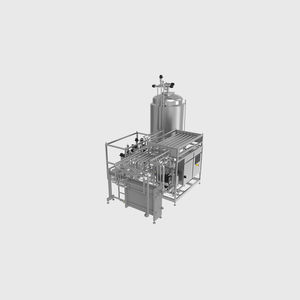

Deaerator for the food industry VARIDOX-Cfor water

Add to favorites

Compare this product

Characteristics

- Options

- for the food industry, for water

Description

Oxygen in beer or beverages may increase product perishability and spoil taste, so using optimally deaerated water for beverage manufacture and for the redilution of beer can have an impact on final quality. The GEA VARIDOX-C cold water deaeration system achieves very low residual oxygen levels, and can be used for different applications.

Deaeration of beverage water

The water is sprayed in the deaeration column and it slowly trickles down the packed columns. At the column outlet the water is saturated with CO2 (N2). If the water is to be used for blending a carbonated product, a precarbonation option is available, configured with a second, separate CO2 line that feeds CO2 to the deaerated water (after the deaeration column).

The system includes probes for flow rate, water or CIP media levels, and, optionally, for oxygen. These sensors monitor the system and how it is functioning. The product line and column are cleaned directly by an efficient CIP system.

Features

Low residual oxygen content: <0.03 mg/l (30 ppb)

Residual oxygen content of: <0.02 mg/l (20 ppb) and 10°C

Control air pressure: 6-8 bar

Materials: 1.4301 / EPDM

CO2 admission pressure: 6-8 bar

CO2 consumption: 0.3–0.8 g/l

CO2 included in the water: 1.7–2.2 g/l

CO2 supply: 2–3 g/l

Catalogs

No catalogs are available for this product.

See all of GEA Wiegand‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.