- Production Machines

- Cutting Machine

- Blocks cutting machine

- Gebr. Schröder GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

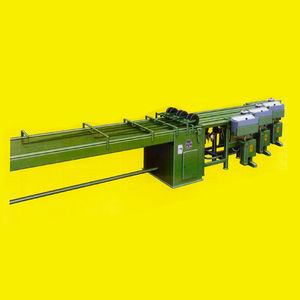

Blocks cutting machine PAKUE FPLC-controlledautomaticroller

Add to favorites

Compare this product

Characteristics

- Product handled

- blocks

- Control type

- PLC-controlled

- Other characteristics

- automatic, roller, 90°, crosscut

Description

Special version based on the precision Double- End Tenoner PAKUE F with roller guided feed chains additionally for Hungarian Point (French Heringbone Parquet with cross angle below 90°), for solid parquet or planks and for pre-finished multi layer parquet (engineered flooring).

Cross-cut angle adjustable (30° - 60° or 90°) by individual high precision Servo-drives for the feed chains (angle accuracy < 0,03 mm).All tool shafts with high precision spindle motors and hydro tool fixture.

As Double-End Tenoner with 3 or 4 spindles each per side for precise cross-cutting and endmatching with T&G as well as additional top face bevel (optional).

Capacity (90° square cut):

length 200 - 1.200 mm; max. 150 pcs. / min.

width 40 - 300 mm; thickness 8 - 30 mm (optional for lengths up to 4.500 mm).

Capacity (Hungarian Point 30° - 60°):

length 300 - 900 mm; max. 80 pcs. / min.

width 40 - 140 mm; thickness 8 - 30 mm

With “regular” hopper for solid parquet and planks as well as additional angular hoppers for “Hungarian Point” (r/h & l/h blocks).

Easy to operate via PLC touch panel; incl. calculation of infeed size (length), automatic tool compensation and calibration device.

With extended feed chains and integrated waste conveyor for off-cuts (specially for Hungarian point / French heringbone).

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.