- Production Machines

- Plastics Processing

- Sheet extrusion line

- GPM Machinery (Shanghai)

- Products

- Catalogs

- News & Trends

- Exhibitions

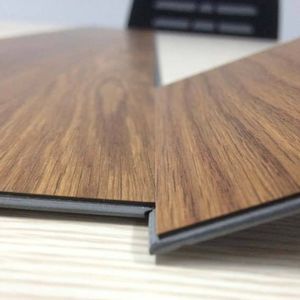

Sheet extrusion line GW120-GF1200for thermoplasticsfor PETmultilayer

Add to favorites

Compare this product

Characteristics

- Type

- sheet

- Treated material

- for thermoplastics, for PET

- Other characteristics

- multilayer

Description

GPM PET sheet production line is for producing defferent PET sheets, the production line is consist of Single screw extruder / Parallel double screw extruder, Hydraulic screen changer, T-die, three roller calender, Haul-off machine, widing machine and cutter, etc.

GPM PET sheet production line is for producing defferent PET sheets, the production line is consist of Single screw extruder / Parallel double screw extruder, Hydraulic screen changer, T-die, three roller calender, Haul-off machine, widing machine and cutter, etc.

Main Features of pet multi-layer sheet extrusion machine:

High degree of automation, high transparency, high output, and can use single screw extruder or twin screw extruder to match defferent needs of customer.

PET Non-crystallization extruding system

The newest screw thread unit, low power consumption, high output, is suitable for PET sheet extruding.

Three roller calender

The high-precision three roller calender forming system, with servo control, hydraulic compress structure, is cuitable for the stable extrusion of sheet thickness at 0.15mm.

Precision die system

Can choose the self-regulation die to realize the change between extrusion mode and casting mode, is suitable for the sheet with different thickness.

Automatic rolling & cutting device

Easy to adjust, cuting straightness is high.

Other GPM Machinery (Shanghai) products

Plastic Sheet Film Extrusion Line

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Pipe extrusion line

- Plastic sheet extrusion line

- Twin-screw screw extruder

- PVC extrusion line

- Polypropylen extrusion line

- Multilayer extrusion line

- Plastic pelletizer

- Polyethylene extrusion line

- Single-screw screw extruder

- HDPE extrusion line

- Drainage pipe extrusion line

- Cast-film extrusion line

- Twin-screw extrusion line

- Plastic profile extrusion line

- PP screw extruder

- PVC screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.