- Metrology - Laboratory

- Metrology and Test Equipment

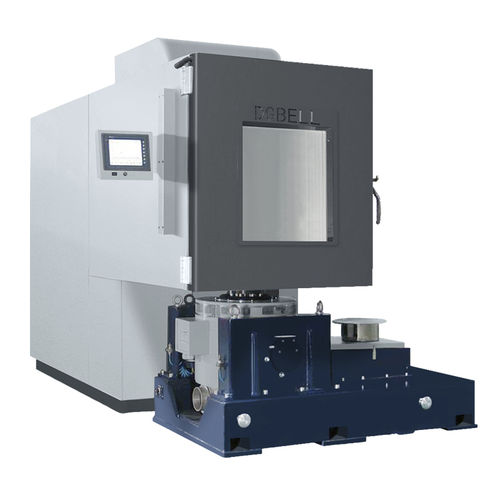

- Humidity test chamber

- Guangdong Bell Experiment Equipment Co., Ltd

Temperature test chamber BTHZ serieshumidityvibrationenvironmental

Add to favorites

Compare this product

Characteristics

- Controlled parameter

- temperature, humidity

- Test type

- vibration, environmental, for rapid temperature cycling

- Application domain

- for the aeronautical industry

- Product applications

- for electrical equipment, for aircraft, for automobiles

- Configuration

- floor-standing

- Options and accessories

- with temperature and climatic control, with constant temperature and humidity control, with window, with cyclical temperature/humidity control

- Other characteristics

- accelerated, low-temperature, stainless steel, for high temperatures

- Capacity

Max.: 1,000 l

(264 gal)Min.: 408 l

(108 gal)- Temperature

Max.: 150 °C

(302 °F)Min.: -70 °C

(-94 °F)- Length

1,650 mm, 1,750 mm

(64.96 in, 68.9 in)- Width

850 mm, 1,250 mm

(33.5 in, 49.2 in)- Depth

1,500 mm, 1,600 mm, 1,800 mm

(59 in, 63 in, 71 in)

Description

The Temperature Humidity Vibration Combined Test Chamber meets national standards and meets specific testing requirements. It is widely used in electrical and electronic products, automotive parts, materials, etc. through a combination of high and low temperature, low temperature, temperature change, impact, wet heat vibration and other environmental reliability tests.

Features

• With high precision perfect external design, external with double sides cold-rolled plate electrostatic powder-coated material, internal with SUS#304 high temperature resistant stainless steel.

• Insulation material adopts fire resistant high strength PU polyurethane foaming thermal insulating material.

• More than 20% of energy saving is achieved &thanks to the introduction of Japan & German advanced refrigerator control technology.

• Control system and control circuit components all introduced with famous brands.

Standard Compliance

• IEC 68-2-1 (GB2423.1-2008)

• IEC 68-2-2 (GB2423.2-2008)

• IEC 68-2-3 (GB2423.3-2006)

• IEC 68-2-30 (GB2423.4-2008)

• IEC 68-2-14 (GB2423.22-2008)

• MIL-STD-810D (GJB150.3A-2009)

• MIL-STD-810D (GJB150.4A-2009)

• MIL-STD-810D (GJB150.9A-2009)

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

The Battery Show - Europe 2024

18-20 Jun 2024 Stuttgart (Germany) Hall E30 - Stand 6

More information

Other Guangdong Bell Experiment Equipment Co., Ltd products

Temperature Humidity Environmental Test Chamber

Related Searches

- Test machine

- Test cabinet

- Material testing machine

- PC-controllable testing machine

- Automatic test machine

- Temperature test cabinet

- Climatic test chamber

- Vertical test machine

- Industrial test machine

- Universal test machine

- Humidity test cabinet

- Digital tester

- Tensile test machine

- Laboratory test machine

- Automatic test equipment

- Precision test machine

- Industrial testing system

- Research and development test machine

- Electromechanical test machine

- Stainless steel test cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.