- Machine-tools

- Cutting Tool

- Corner radius milling cutter

- MOLDINO Tool Engineering Europe GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

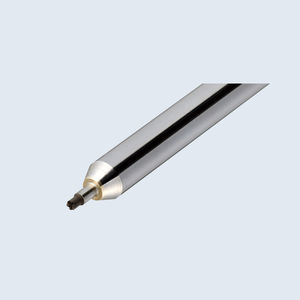

Corner radius milling cutter EMXA seriessolidplungefor aluminum

Add to favorites

Compare this product

Characteristics

- Geometry

- corner radius

- Construction

- solid

- Type

- plunge

- Treated material

- for aluminum, for copper, for aluminum alloys

- Other characteristics

- cutting edge, high-precision, high-efficiency, high-speed, with cylindrical shank, 2-flute, 3-flute

- Diameter

Min.: 3 mm

(0.12 in)Max.: 25 mm

(0.98 in)- Length

Min.: 60 mm

(2.36 in)Max.: 150 mm

(5.91 in)

Description

Designed with large-rake-angle end cutting edge

High-efficiency also for plunge cutting in Z direction!

Enables stable machining without chattering even for high-speed machining!

Special flute shape design provides both good chip removal characteristics and high cutting edge strength.

2-Flutes type

To provide both good chip removal and high cutting edge rigidity,

(1) Chip pockets are larger than previous designs.

2) Cross-section is larger to secure cutting edge strength

This enables high-speed machining of aluminum alloys.

3-Flutes type

Ideal flute groove design for aluminum machining

Uses a groove shape that provides good chip flow. In addition, the cutting edge has low cutting resistance to handle high-speed machining of aluminum alloys.

Enables high-efficiency cutting in Z direction. Best lineup suitable for machining size .

End cutting edge with focus on cutting performance enables high-feed-rate cutting in Z direction.

The end cutting edge on both 2-flutes and 3-flutes types are sharp design to provide low cutting resistance. This enables high-efficiency machining even for Z-direction machining.

2-Flutes type

For high-efficiency cutting on high-speed machining centers

・Enables high-efficiency machining with high-speed machining centers.

・Cutting chips flow out smoothly due to mirror-surface-finished flute groove even with non coating.

・Can handle any machining, such as plunge machining, contouring, inclined machining, etc.

・Select the optimum corner R for the machining dimensions. (※Semi-order products)

・Stable machining can be performed using the optimum overall length for the shrink-fit holder.

Catalogs

PRODUCTS CATALOGUE 2015 - 2016

1070 Pages

EMXA

12 Pages

Other MOLDINO Tool Engineering Europe GmbH products

Endmills

Related Searches

- Moldino milling cutter

- Moldino solid milling cutter

- Moldino steel milling cutter

- Drilling tool

- Moldino clamping milling cutter

- Solid drilling tool

- Moldino milling cutter with cylindrical shank

- Moldino metal milling cutter

- Moldino insert milling cutter

- Moldino end mill

- Moldino coated milling cutter

- Moldino cast iron milling cutter

- Moldino cutting milling cutter

- Moldino ball nose milling cutter

- Shell-end milling tool

- Moldino roughing milling cutter

- Face milling tool

- Moldino corner radius milling cutter

- Carbide drilling tool

- Moldino indexable insert milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.