- Machine-tools

- Cutting Tool

- Indexable insert milling cutter

- MOLDINO Tool Engineering Europe GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

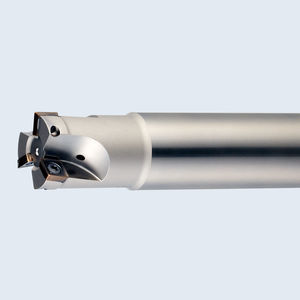

Indexable insert milling cutter AME seriesroughingsemi-finishingcoated

Add to favorites

Compare this product

Characteristics

- Construction

- indexable insert

- Type

- roughing, semi-finishing

- Material

- coated

- Treated material

- for stainless steel, for carbon steel, for cast iron, for titanium, for titanium alloys

- Other characteristics

- cutting edge, high-efficiency, square-head, with cylindrical shank, deep-cutting

- Diameter

32 mm, 40 mm, 50 mm, 63 mm

(1.26 in, 1.57 in, 1.97 in, 2.48 in)- Length

Min.: 55 mm

(2.17 in)Max.: 220 mm

(8.66 in)

Description

・Employs an AlTiN layer with a new composition created by increasing the Al content of conventional layers.

・Excellent wear resistance, chipping resistance, and heat resistance!

New technology!!

・The new layer with high Al content employs a new composition and optimizes the structure to improve wear resistance and chipping resistance!

・Employs a low-friction-effect coating with excellent welding resistance as the top-most surface layer. This reduces welding to the work and decreases cutting force!

Features

・Employs a carbide substrate with high toughness and the new "AJ Coating" to improve wear resistance and chipping resistance when machining stainless-steel materials.

・ Employs AJ Coating with excellent welding resistance to reduce the welding to work material that occurs when machining stainless steel materials.

Strong fields

・Provides long tool life for general processing of stainless-steel materials.

VIDEO

Catalogs

Roughing End Mill AME Type

12 Pages

Other MOLDINO Tool Engineering Europe GmbH products

Indexable tool

Related Searches

- Moldino milling cutter

- Moldino solid milling cutter

- Moldino steel milling cutter

- Drilling tool

- Moldino clamping milling cutter

- Solid drilling tool

- Moldino milling cutter with cylindrical shank

- Moldino metal milling cutter

- Moldino insert milling cutter

- Moldino end mill

- Moldino coated milling cutter

- Moldino cast iron milling cutter

- Moldino cutting milling cutter

- Moldino ball nose milling cutter

- Shell-end milling tool

- Moldino roughing milling cutter

- Face milling tool

- Moldino corner radius milling cutter

- Carbide drilling tool

- Moldino indexable insert milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.