- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

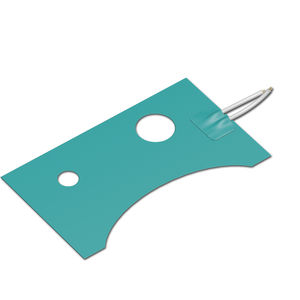

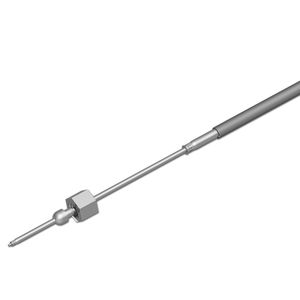

Liquid nozzle hotcastfor the steel industryfor high-temperature applications

Add to favorites

Compare this product

Characteristics

- Fluid

- for liquids

- Applications

- for the steel industry, for high-temperature applications

Description

The heated sprue nozzle brings the point of thermal separation to the mold-parting surface and eliminates the major of the sprue excess material. Cycle times decrease up to 40 % and provide better part quality.

Up to 40% reduced cycle time

Up to 30% reduced shot size

Up to 7% increased part weight due to higher microstructure density

Improves part quality

Reduces porosity and eliminates costly sprue cone

Decreases tool costs

Traditional cold plug nozzles can be replaced by the hotcast sprue nozzle

Increased design options with new mold design e. g. smaller plate thickness

Less scrap after electro-plating finishing, e.g. improved surface

Continuous heating from goose neck to the mold

Integrates into 50T and 80T die-casting machines

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.