• Robust design for harsh environments

• Lifting range up to 30 m

• Standardised levelling elements

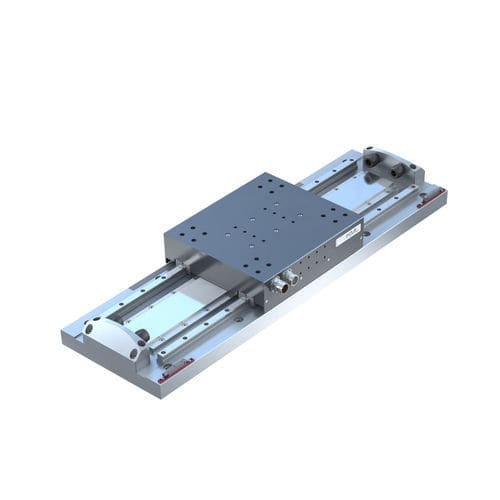

The LMS E series was specially developed for applications where high dynamics, freedom from maintenance and robust mechatronics are required in conjunction with high customer masses. Stroke lengths of over 2 m can also be implemented. Available in economy and high-precision versions, the LMS E series guarantees unbeatable motion quality for medium loads up to approx. 30 kg or 100 kg, at the price level of conventional drive solutions.

The base axis and the optimised cross beam axis ensure high inherent stiffness. The cross beam axis can be fully supported or alternatively cantilevered. The standardised levelling elements enable simple and safe alignment of the linear motor systems on unmachined machine frames, which means that cost-intensive machining over longer lengths can be avoided. Both versions can be used as single axis units or combined with the standardised connection elements to form multi-axis systems ex works.

Due to the robust yet precise feedback or length measuring systems, the LMS E series can be used in almost all industry sectors. Systems in the LMS E series fulfil the requirements of the currently valid Machinery Directive.

• Automation systems

• Area gantry robots

• Feeding systems

• Dispensing systems

• Laser processing

• Automatic placement systems

• Soldering systems

• Inspection gantries

• Glass and plastics industry

• Metalworking industry

• Solar and photovoltaic industry

• Semiconductor and electronics industry