- Detection - Measurement

- Optical and Acoustic Measurements

- Flatness interferometer

- Lamtech Lasermesstechnik GmbH

Flatness interferometer SPI, PGI Seriesground parts

Add to favorites

Compare this product

Characteristics

- Applications

- flatness, ground parts

Description

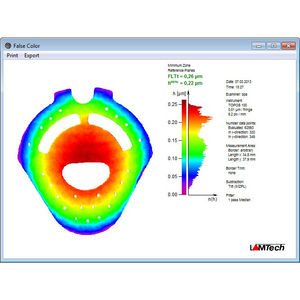

SPI and PGI - Interferometers for visual flatness check of precision parts

Lamtech Lasermesstechnik offers interferometers for visual flatness check of finish-machined (SPI) as well as polished (PGI) parts.

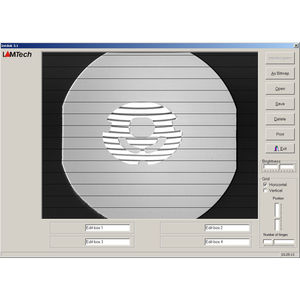

In order to evaluate the test object, the part is placed on the glass surface of the SPI or PGI. Part and fringes are than presented enlarged on the video monitor. The evaluation of the flatness happens on the basis of interpretation of the straightness, parallelism and equidistance of the interference fringes shown on the monitor.

The interferometers are suitable to be placed in the production area close to the processing machines.

The Program INTDOK (more) or a video printer enable the documentation of the flatness of parts.

Visual inspection interferometer SPI – for visual flatness check of finish-machined surfaces

SPI visual inspection instruments allow the flatness check of lapped, ground or polished surfaces. Like the TOPOS flatness measurement instrument, the SPI interferometer is also based on the principle of grazing incidence of light. Thus, with the SPI interference fringes are visible with matte test objects. The part does not have to be polished before the examination with the SPI.

SPIs are available with a measuring field of 75 and 130mm.

Additionally, we offer the SPI-xs with enhanced sensitivity. The sensitivity is set up to 0.3 µm/fringe, which corresponds to the sensitivity of the measurement with an optical flat and a helium or sodium lamp.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.